In oil drilling operations, the shale shaker screen is critical wear-resistant component of drilling mud shale shaker, playing decisive role in filtering solid impurities and maintaining drilling fluid performance for effective drilling mud solids control. The type of oilfield shale shaker screen directly affects screening efficiency and operational costs, and among the various types available, steel frame shaker screens and hook strip shaker screens are the most widely applied in industrial scenarios. TR Solids Control, professional manufacturer specializing in drilling mud solids control equipment, elaborates on the core differences, structural characteristics, advantages, and applicable scenarios of these two shale shaker screen types to provide a reliable reference for drilling screen selection. Additionally, we introduce premium API standard shaker screen solutions that meet international industry requirements.

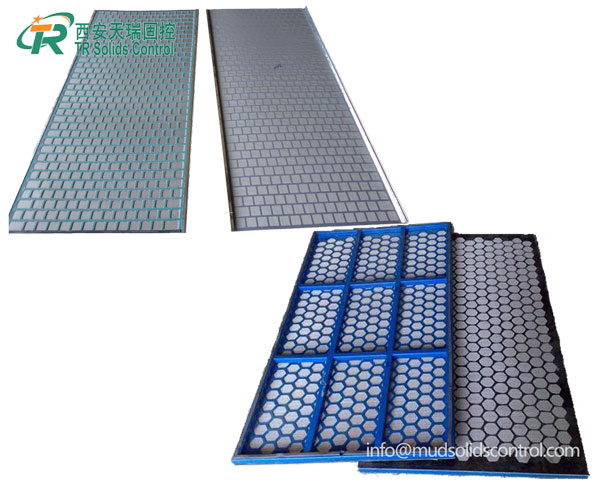

The fundamental difference between frame shaker screens and hook strip shaker screens lies in their structural design and installation methods, which directly determine their performance features and suitable working conditions for drilling mud solids control. As key components for oil drilling mud treatment, both types adopt fully bonded laminated structure: a corrosion-resistant adhesive is applied between the perforated metal plate and the screen cloth to form firm bonding layer, ensuring stable screening performance during high-intensity operations— a crucial requirement for API standard shaker screens.

Simply put, frame shaker screens are fixed via a "frame + compression device" assembly, while hook strip shaker screens are tensioned through a "hook strip + metal backing plate" system. Each design is tailored to distinct drilling requirements, ensuring optimal efficiency in different drilling mud solids control scenarios.

The steel frame shaker screen is staple in oilfield shale shakers, offering balanced advantages in easy installation and structural strength—key factors for minimizing downtime in drilling mud solids control operations. Its structure consists of two core parts: first, high-strength steel frame welded from square steel pipes or flat steel, equipped with multiple reinforcing ribs to prevent deformation under high-frequency vibration and high-flow material impact; second, 2–3 layers of stainless steel screen cloth, which are tightly bonded to the frame via metal rubber lining or direct adhesion. The mesh sizes of each layer are precisely matched to achieve fine classification screening, a standard feature of high-quality frame shaker screens.

In terms of installation, the frame shaker screen uses wedge-type quick tensioning device, which fixes the frame to the shale shaker box through wedges or compression components. Its most notable advantage is convenient and fast replacement, which significantly shortens downtime—making it ideal for continuous drilling operations and working conditions requiring frequent screen changes to maintain consistent drilling mud solids control efficiency. Meanwhile, the high-strength frame and tensioned screen form a stable integrated structure, enhancing flow carrying capacity and extending the service life of the frame shaker screen.

The hook strip shaker screen is designed with "local protection + cost-effective repair" as its core concept, making it a cost-efficient choice for drilling mud solids control in harsh conditions. Structurally, it is high-strength integrated component composed of 2–3 layers of stainless steel screen cloth closely attached to perforated metal backing plate. A key feature is that the metal backing plate divides the screen surface into multiple independent small areas, which effectively prevents the expansion of local damage and extends the overall service cycle of the hook strip shaker screen.

For installation, the hook strip shaker screen is tightly fixed to the shale shaker box using special hook strips, ensuring structural stability even in complex drilling conditions. During operation, if local screen surface damage occurs, it can be quickly repaired with special rubber plugs without replacing the entire screen—greatly reducing replacement costs and downtime for drilling mud solids control operations. In addition, by optimizing the screen mesh size, the punching shape, and the open area ratio of the metal backing plate, the hook strip shaker screen achieves maximum effective filtration area while ensuring structural strength, thereby improving screening precision and efficiency. Like high-quality frame shaker screens, premium hook strip shaker screens also comply with API standards to guarantee performance reliability.

The selection of oil drilling shaker screens should be based on two key indicators—material characteristics and operating conditions—combined with the performance advantages of two screen types to ensure optimal drilling mud solids control results. Here are the expert selection suggestions:

1. For continuous high-intensity drilling operations with large material flow rates, where frequent screen replacement is required to ensure consistent efficiency, frame shaker screens are preferred. Their quick-installation design minimizes downtime, and the high-strength frame is well-suited for withstanding high-flow impact, ensuring stable drilling mud solids control.

2. For drilling operations in complex formations with highly abrasive solid materials, or where local screen damage is prone to occur, hook strip shaker screens are the optimal choice. The independent small screen surfaces prevent damage expansion, and the convenient rubber plug repair function reduces operational costs, making it practical option for long-term drilling mud solids control.

3. Regardless of the screen type selected, priority should be given to API standard shaker screen products (equivalent to SY/T 6614-2005). API standard shaker screens guarantee screening precision and structural stability, avoiding adverse effects on drilling fluid performance and ensuring compliant and reliable drilling mud solids control.

TR Solids Control is professional shale shaker screen manufacturer with in-depth expertise in the oil drilling solids control field. Both our frame shaker screens and hook strip shaker screens strictly comply with API standards, undergoing rigorous quality testing to meet the high demands of drilling mud solids control operations. Through precise structural design and high-quality material selection, our API standard shaker screens achieve breakthrough performance: compared with ordinary shaker screens, TR’s API-standard shale shaker screens can improve shale shaker separation efficiency by 35%, extend service life, and significantly reduce replacement frequency and operational costs.

For different drilling conditions, TR Solids Control provides customized shale shaker screen solutions. We optimize screen mesh size matching, frame/backing plate materials, and adhesive formulas according to specific factors such as material viscosity, solid particle size, and corrosivity. This ensures that our frame shaker screens and hook strip shaker screens are precisely matched to operational needs, providing reliable support for efficient and stable drilling mud solids control.

In summary, the core differences between frame shaker screens and hook strip shaker screens lie in their structural design and installation methods—the former emphasizes efficient and convenient replacement, while the latter focuses on cost-effective and durable repair. In oil drilling operations, the correct selection should be based on material characteristics, operational intensity, and cost requirements, with priority always given to API standard shaker screen products to ensure drilling mud solids control quality. With standardized and customized shale shaker screen solutions, TR Solids Control helps drilling projects reduce costs and increase efficiency, providing reliable equipment support for the global oil drilling industry.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li