In the oil drilling solids control system, the shaker screen is a critical component that separates drill cuttings from drilling mud and ensures mud recycling and reuse. Its selection directly impacts drilling efficiency, mud loss, and overall production costs. Currently, two mainstream shaker screen types—flat shaker screen (PWP) and wave shaker screen (PMD), exhibit distinct application characteristics due to structural design differences. This article explores their core features, key distinctions, and provides precise selection solution based on material properties, screening requirements, and drilling conditions, helping you make an informed decision for your oilfield operation.

Oilfield shale shaker screens leverage high-speed vibration of shale shakers to efficiently separate solid impurities (e.g., drill cuttings) from drilling mud, ensuring stable performance of circulating mud and thus realizing mud recycling, which reduces drilling costs. Drilling mud is mainly divided into water-based mud (WBM) and oil-based mud (OBM), and their corrosivity and viscosity impose different requirements on shaker screen materials and structures:

● Oil-based mud has strong corrosivity, so shaker screens made of 304 or 316L stainless steel are preferred for oil-based mud applications.

● Water-based mud has relatively low viscosity, requiring higher anti-clogging performance of the shaker screen.

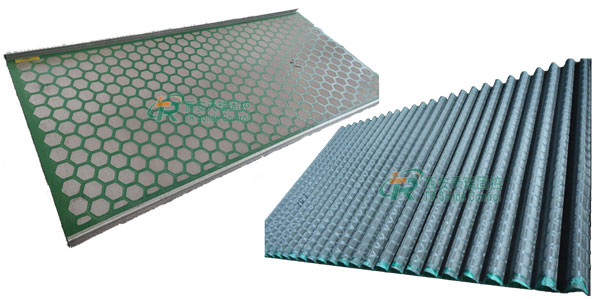

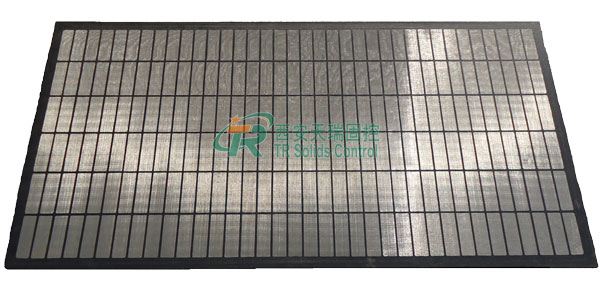

Flat Shaker Screen (PWP): Cost-Effective for Basic Needs

Flat shaker screens are manufactured by bonding two layers of stainless steel mesh to steel plate at high temperature, enabling them to withstand high-temperature working environments. The production process includes sheet punching → sheet cutting → sandblasting → mesh cutting → mesh-steel plate bonding → edge hemming → packaging, featuring simple and stable structure.

Core advantages of flat shaker screens focus on cost control and easy maintenance:

● Low overall cost: The flat structure allows 4 screens to be loaded per box, significantly lowering transportation costs besides the low manufacturing cost.

● Convenient maintenance: Damaged screen surfaces can be quickly repaired with specialized shaker screen repair patches, minimizing maintenance downtime.

● Wide compatibility: Suitable for most conventional drilling equipment, especially ideal for basic drilling conditions with low requirements for screening efficiency.

Wave Shaker Screen (PMD): High-Efficiency for Complex Conditions

Wave shaker screens are characterized by unique wave-shaped surface and flexible installation methods, which can be fixed by edge hemming or wedge compression devices for steel frame screens. In the manufacturing process, 2–3 layers of mesh are first bonded, then pressed into wave shape, and finally bonded to steel plate to ensure the stability and screening strength of the wave structure.

The most prominent advantage of wave shaker screens is the significant improvement in screening efficiency:

● The wave-shaped design increases the effective screening area to 125%–150% of that of flat shaker screens of the same specification. Under the same vibration frequency, the mud processing capacity is greatly improved, effectively reducing fine particle loss and enhancing mud recovery quality.

● The wave structure enables uniform material distribution on the screen surface, reducing local accumulation and clogging. It is particularly suitable for high-viscosity mud or large-displacement drilling conditions.

| Comparison Dimension | Flat Shaker Screen (PWP) | Wave Shaker Screen (PMD) |

| Effective Filtration Area | Standard area, suitable for basic processing capacity | Increased by 25%–50%, outstanding for large processing capacity |

| Core Advantages | Low cost, reduced transportation fees, easy damage repair | High screening efficiency, excellent anti-clogging, high mud recovery rate |

| Manufacturing Cost | Lower, simple processing procedures | Higher, additional wave-pressing forming process |

| Maintenance Difficulty | Simple, repairable on-site quickly | Complex, hard to repair after wave structure damage |

| Compatible Mud Types | Priority for water-based mud; compatible with conventional oil-based mud | Compatible with both water-based and oil-based mud; ideal for high-viscosity oil-based mud |

The selection of shale shaker screens should comprehensively consider material properties, screening requirements, drilling conditions, and cost budgets, adhering to the core principle of "matching working conditions and balancing efficiency and cost".

Material Particle Size & Hardness

● Large drill cuttings (> 2mm, e.g., loose formations) with low hardness: Choose flat shaker screen, matching 20–60 mesh large-aperture surfaces to meet basic screening needs and control costs.

● Fine drill cuttings (< 0.5mm, e.g., hard formations) with high hardness: Select 316L stainless steel wave shaker screen, pairing with 80–120 mesh small-aperture surfaces to ensure precise separation of fine particles; the wave structure can disperse material impact force and extend screen service life.

Material Moisture & Mud Viscosity

● High moisture content (water content > 8%) and high-viscosity mud (e.g., sticky cuttings, high-viscosity oil-based mud): Prone to adhesion and clogging, so wave shaker screen is preferred. The wave-shaped surface extends the material sliding path to reduce accumulation; rectangular mesh holes are recommended to further enhance anti-clogging effects.

● Dry material and low-viscosity mud: Flat shaker screen can meet the requirements with higher cost-effectiveness.

Screening Efficiency & Processing Capacity Requirements

● Large pump displacement (daily processing capacity > 1000 m³) and high efficiency requirements (e.g., offshore platforms, deep drilling): Wave shaker screen is a must, as its large screening area ensures rapid mud separation and avoids mud waste due to delayed processing.

● Onshore shallow wells and small-scale drilling (daily processing capacity < 800 m³) with low efficiency requirements: Flat shaker screen is suitable to effectively control procurement and operation costs.

Mud Type & Cost Budget

● Water-based mud with limited budget: Prioritize flat shaker screen, which can save 30%–50% of procurement costs.

● Oil-based mud: Recommend wave shaker screen; although the initial investment is higher, it can increase the mud recovery rate by more than 25%, reducing overall costs in the long run.

Operating Environment (Extreme Condition Adaptation)

Different operating environments have varying requirements for screen material and corrosion resistance:

● High-salt corrosive environments (e.g., offshore platforms): Prioritize 316L stainless steel for both screen types.

● Conventional onshore environments: Ordinary stainless steel flat shaker screen can meet the needs.

● High vibration frequency (> 30Hz) of shale shaker: Wave shaker screen’s steel frame wedge compression device is more stable to prevent screen deviation; flat shaker screen requires additional reinforcement for installation.

Flat shaker screens and wave shaker screens each have unique advantages and applicable scenarios in drilling operations. To summarize: choose flat shaker screen for low-cost and basic screening needs; opt for wave shaker screen for high efficiency, large processing capacity, and complex working conditions. When selecting, consult shaker screen manufacturers based on cutting parameters, mud properties, and equipment models to ensure precise matching between the screen and working conditions. In daily use, regularly inspect screen tension and wear: repair damaged flat shaker screens promptly, and focus on maintaining the frame fixing devices of wave shaker screens. These measures can effectively extend service life and reduce overall production costs.

TR Solids Control is a manufacturer of solids control equipment and shale shaker screens, offering replacement screens for Derrick and Swaco equipment. For custom orders, please contact: info@mudsolidscontrol.com

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li