In oil drilling operations, shale shaker screens separate solid particles from drilling fluids, ensuring the cleanliness and stable performance of the drilling fluid. As a wear-prone component, choosing the right brand and model of replacement screen is crucial for efficient drilling. TR Solid Control specializes in the production of solid control equipment and provides high-quality replacement screens compatible with mainstream shale shakers, helping to reduce costs and improve efficiency in drilling operations.

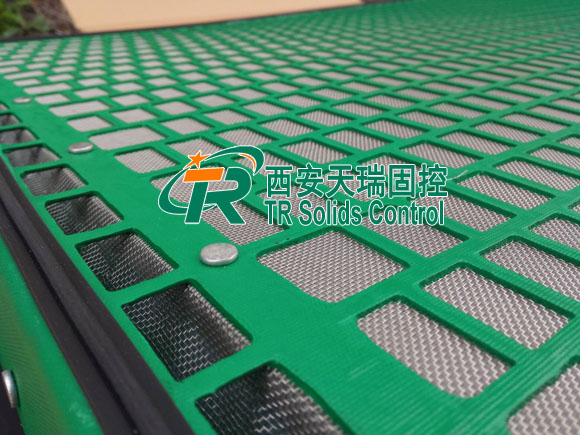

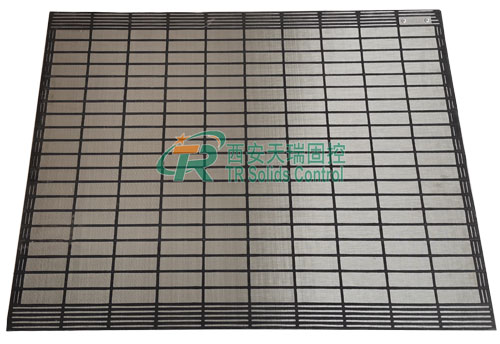

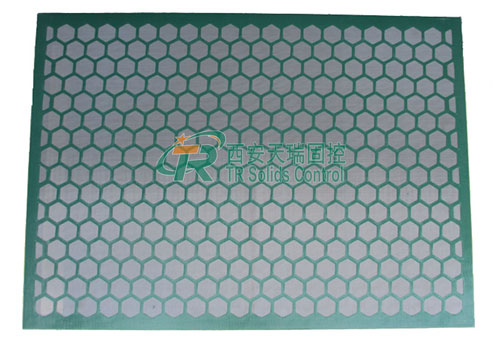

Common types of shale shaker screens for oil drilling include Hook Strip Flat Screen, Pyramid(wave) Screen, Steel Frame Screen, Composite Screen and Polyurethane Screen。Different brands of shale shakers vary significantly in screen size and tensioning requirements. Currently, for leading market shale shakers such as Derrick and Swaco, TR Solids Control offers precisely matched replacement screen models, and can also be custom-manufactured according to specific working conditions.

Shale shaker screen performance directly impacts project schedule, costs, and safety. Are your shaker screens wearing out too quickly, requiring frequent replacements and resulting in high costs? Is the screening efficiency unsatisfactory, leading to high sand content in the drilling fluid and causing wear on downstream equipment? Faced with the wide variety of shaker screen products on the market, TR Solids Control, as a professional manufacturer of solids control equipment, helps you analyze the key factors for screen selection.

Match Working Conditions and Drilling Fluids

Soft formations: Use low frequency and large amplitude combined with 80-mesh screen to prevent mud from clogging the drill bit.

Hard rock formations: Switch to high frequency, small amplitude settings with 120-mesh screen to control abrasive particles.

Deep well operations: Activate low-temperature drilling fluid mode, and adjust the screen surface inclination to 3° to prevent screen embrittlement.

Water-based drilling fluid: Conventional mud, select 100-mesh screens to balance cost and efficiency. High-viscosity mud uses polyurethane screens or Brandt VSM300 screens to reduce risk of clogging and ensure smooth screen surface to minimize mud retention.

Oil-based/synthetic-based drilling fluids: Use 50-200 mesh polyurethane screens to improve corrosion resistance and prevent clogging.

Understanding materials and craftsmanship

Made from 304/316 stainless steel, this material is suitable for highly corrosive and abrasive environments, extending the service life of shaker screen.

TR Solids Control utilizes fully automatic precision weaving technology and advanced double-fixing process of hook edging and adhesive bonding to ensure uniform screen tension. This prevents detachment and deformation during intense vibration, effectively eliminating the "coarse particle leakage" phenomenon.

Precisely Match Shale Shaker Models

Different brands of shale shakers have different requirements for screen mesh size and tensioning methods. TR Solids Control provides customized services, and our products are interchangeable with screen meshes from Derrick and Swaco models.

Balance Mesh Size and Processing Capacity

Generally, a higher mesh count means finer screening. However, a higher mesh count isn't always better. The appropriate mesh size needs to be matched to the drilling conditions and processing volume to maximize processing efficiency while ensuring screening quality, thus facilitating faster drilling.

TR Solids Control's replacement screen panels undergo rigorous quality testing, offering wear resistance and impact strength far exceeding industry standards. This significantly reduces replacement frequency and lowers overall costs by more than 30%. We not only provide stable supply of standard models but also offer efficient customization, eliminating intermediaries through direct factory sales. We provide quality comparable to international brands at more competitive price, truly helping you reduce costs and improve efficiency, providing cost-effective screen panel solution for oil drilling operations.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li