Drilling Mud Cooler, also known as mud cooling device or mud cooling system, is specialized device used to cool high-temperature mud in the well during drilling. TR Petroleum's independently designed and developed new mud cooling system allows the hot drilling fluid (mud) flowing from the wellhead to be transported to the system's inlet manifold via a manifold. The temperature difference between the mud before and after treatment by the mud cooling system is 30-40°C, effectively extending the service life of the drill bit and drill pipe while improving drilling efficiency.

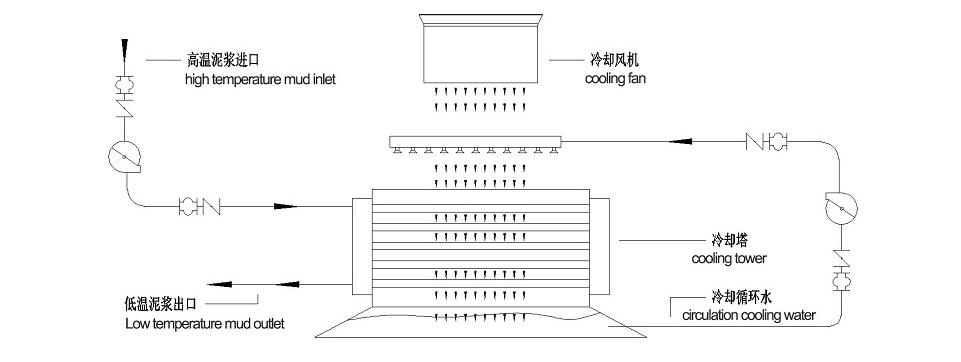

The working process of drilling mud cooler is that The High-temperature mud into the mud cooling system, cooling water to the fan on the cooling tower to provide high-intensity cold air and circulating cooling water, when the high-temperature mud in the cooling tower circulation, due to the role of the fan and the cooling water, continue to emit large amount of heat, the available low-temperature mud will be from the bottom of the cooling tower pipeline out to achieve the work of mud cooling.

| Exhaust system | Water Cooling System | Mud System | |||

| Dimension | 1000mm | Inlet (Water)Dimensions | 2.5'' | Inlet (Slurry) Dimensions | 8"(DN150) |

| Blade Quantity | 10 | Outlet (Water)Dimensions | 3'' | Outlet(Slurry)Dimensions | 6"(DN125) |

| Voltage | Customize | Voltage | Customize | Voltage | Customize |

| Generator Type | Explosion-proof | Generator Type | Explosion-proof | Generator Type | Explosion-proof |

| Power | 7.5kw | Power | 22kw | Power | 55kw |

| Flow | 600m³/min | Flow | 160m³/min | Flow | 318m³/min |

| Driving Mode | Direct Drive | Radiator | 2.5'' | Number of nozzles | 4 |

| Number of Radiators | 36×0.57" | Pipe Volume | 2423m³ | ||

| Driving Mode | Direct Drive | Copper Cooling Area | 189571m² | ||

| Inlet and Outlet Temperature Difference | 50-60℃ | ||||

Drilling fluid cooling systems are critical equipment in oil drilling operations, primarily used to control drilling fluid temperature and ensure safety and efficiency. In high-temperature formations or deep well drilling, drilling fluid cooling systems utilize efficient heat exchange technology to cool high-temperature drilling fluid to an appropriate temperature, maintaining its stable performance and extending equipment life. These systems typically consist of cooling unit, circulating pump, radiator, and control system. Water cooling, air cooling, or hybrid cooling method can be selected based on specific needs.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li