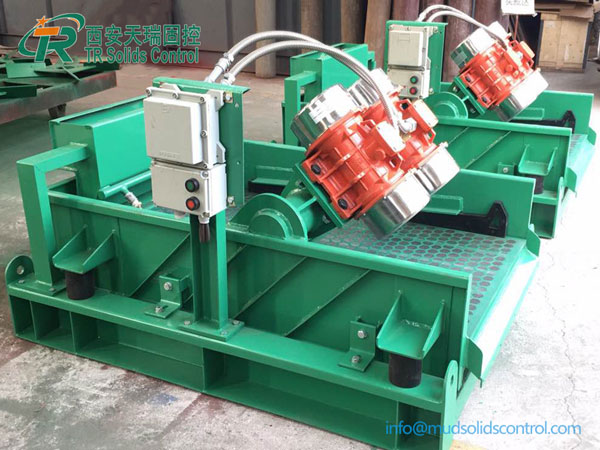

The drilling shale shaker is core solid-liquid separation device in solids control system for oil and gas drilling. Its performance directly determines the mud purification effect and the overall cost of drilling operations. Based on differences in vibration trajectory, structural design and functional features, the mainstream types of drilling shale shakers on the market can be classified into the following categories, each perfectly adapted to the requirements of different drilling conditions.

The linear motion shale shaker generates linear motion through a pair of eccentric shafts rotating in opposite directions, providing excellent cutting, conveying and screening capabilities while helping to retain more drilling fluid. As high-efficiency drilling shale shaker, it is particularly suitable for handling large-flow drilling fluid and can effectively separate large-size drill cuttings from the mud. Its stable linear motion trajectory ensures consistent separation performance, making it common choice in basic oil and gas drilling operations.

The translational elliptical motion shale shaker is renowned for its high vibration intensity and efficient solid-liquid separation performance among drilling shale shaker types. Its elliptical vibration trajectory not only can effectively remove solid impurities from drilling fluid, but also reduces screen mesh wear significantly—extending the service life of the drilling shale shaker and lowering maintenance costs. The elliptical motion path is more consistent with the flow characteristics of drilling mud, endowing the shaker with stronger adaptability to complex drilling conditions such as high-pressure and high-temperature wells.

The double-deck shale shaker adopts dual-layer screen mesh design, realizing graded filtration through shaker screens with different aperture sizes. The upper layer of this drilling shale shaker separates large-particle drill cuttings, while the lower layer conducts fine purification of drilling mud. This design enables multi-stage purification in single operation, significantly improving the recovery and utilization rate of mud. With compact structure and small floor space, this type of drilling shale shaker is ideal for deep well and ultra-deep well drilling operations that require high precision of mud purification.

The dual-trajectory shale shaker is versatile drilling shale shaker that can flexibly switch between vibration trajectories (linear/elliptical) according to drilling working conditions. It combines the advantages of linear motion shale shaker and elliptical shale shaker to achieve more efficient solid-liquid separation, making it suitable for diversified drilling environments. Featured with convenient adjustment, it can cope with drilling mud with different viscosities and sand contents.

The frequency conversion shale shaker is an intelligent drilling shale shaker that realizes flexible adjustment of vibration intensity by regulating the frequency of the vibration motor. It can real-timely adjust vibration frequency and amplitude according to mud flow rate and sand content. When drilling parameters fluctuate greatly, it can accurately match the working condition requirements, maintain stable purification effect and reduce energy consumption. With high intelligence, this type of shale shaker is suitable for automated drilling operation systems.

On the basis of solid-liquid separation, the drying shale shaker further performs drying treatment on solid particles. While separating drill cuttings, it reduces the water content of cuttings, minimizing the amount of waste to be disposed of and alleviating environmental pressure. It is suitable for drilling operations with strict requirements on solid waste treatment, conforming to the development trend of green drilling.

The negative pressure shale shaker(Vacuum Shale Shaker) utilizes the negative pressure principle to enhance the adsorption capacity of the screen mesh for fine particles, improving the fineness of solid-liquid separation. This type of drilling shale shaker has strong anti-clogging ability, and is suitable for the purification of high-density and high-viscosity drilling mud, showing distinct advantages in drilling operations in complex formations.

When selecting the type of drilling shale shaker, it is necessary to make a comprehensive judgment based on working condition parameters such as drilling depth, mud characteristics, and environmental protection requirements. As a professional manufacturer of solids control equipment, TR Solids Control provides full range of drilling shale shaker products, including linear motion shale shaker, elliptical shale shaker, double-deck shale shaker, and more. Our drilling shale shakers are featured with large exciting force, wide screen surface and high cost performance, which are widely used in oilfield drilling operations at home and abroad. We can also meet the customized needs of different drilling scenarios.

If you are looking for reliable drilling shale shaker supplier, please feel free to contact TR Solids Control for more product information and customized solutions.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li