In oil drilling operations, stable drilling fluid performance is critical to drilling efficiency and downhole safety. The "3 Removers 1 Shaker" equipment package, as the core of drilling fluid solids control systems, removes harmful solids and gases from drilling fluid through graded collaborative processing, safeguarding smooth drilling operations. What exactly are these four pieces of equipment, and what functions do they perform? TR Solids Control breaks it down clearly.

The "3 Removers 1 Shaker" refers to three separation devices (desander, vacuum degasser, desilter) and one screening device (shale shaker). Following the principle of "coarse-to-fine, solids-first-then-gas" graded treatment, these four devices work synergistically to remove large cuttings, medium sand particles, fine silt particles, and dissolved gases from drilling fluid step by step. This prevents drilling fluid performance degradation caused by harmful solid accumulation and gas contamination, thereby reducing the risk of downhole accidents such as blowouts and drill string wear.

As the first line of defense in the drilling fluid solids control system, the shale shaker undertakes the initial solid-liquid separation to reduce the load for subsequent equipment. It separates particles larger than 74μm via high-frequency vibration. When drilling fluid containing large cuttings circulates back from the wellbore, it flows through the pipeline from the wellhead to the mud tank into the shale shaker. The shaker screens out cuttings larger than 74μm, completing the first-stage solids control.

The shaker screen plays a key role in the shale shaker. Different screen apertures separate large-sized solids (cuttings) in the drilling fluid. The selection of screen material and aperture is crucial. High-quality shaker screens feature excellent wear resistance and precise particle size control, meeting the requirements of diverse drilling conditions. In oilfield solids control systems, the shale shaker is an irreplaceable component of the "3 Removers 1 Shaker" package.

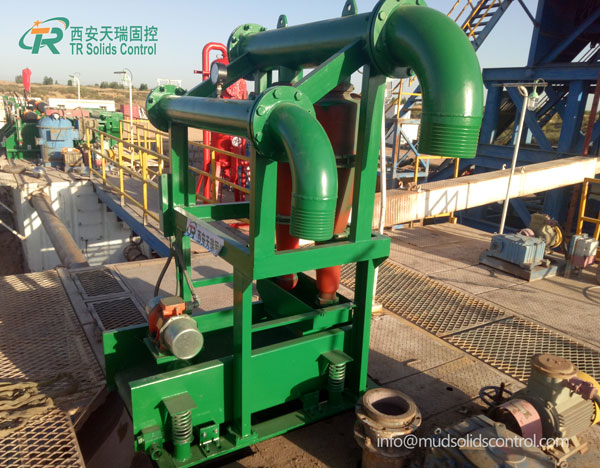

After primary treatment by the shale shaker, the drilling fluid enters the desander. Operating on the centrifugal force principle, the desander injects drilling fluid into the hydrocyclone tangentially at specific pressure. During high-speed rotation, centrifugal force flings high-density sand particles toward the cyclone wall, which then move downward and discharge through the bottom sand outlet. Meanwhile, low-density drilling fluid flows out from the top overflow port.

The desander’s core technology lies in hydrocyclone structural design and working pressure control, proper parameters ensure high-efficiency sand removal. It separates medium-sized particles ranging from 45–74μm and is usually equipped with 20–40 mesh screens. Working in tandem with the shale shaker, the desander further purifies drilling fluid in the solids control system.

The desilter handles fine particles from 10–44μm using small-diameter hydrocyclones, also based on the centrifugal force principle. Its smaller hydrocyclone diameter generates stronger centrifugal force, enabling the separation of micron-level particles.

As a key component in ensuring drilling fluid quality, the desilter plays a vital role in controlling drilling fluid solid content and improving fluid performance, guaranteeing smooth drilling processes.

During drilling, formation natural gas or air may invade the drilling fluid, a phenomenon known as gas invasion. Gas invasion reduces drilling fluid density, disrupting the liquid column pressure balance. If left untreated, it can trigger severe safety accidents such as blowouts.

The vacuum degasser removes invading gases from drilling fluid via vacuum or centrifugal action, restoring fluid density and ensuring drilling safety. Its working principle is based on gas solubility equilibrium law: gas solubility in liquids is proportional to its partial pressure. The equipment creates and maintains a negative pressure environment in a sealed container, reducing the partial pressure of dissolved gases and promoting their release from drilling fluid. The released gas is extracted and discharged under negative pressure, while the degassed drilling fluid regains normal density and re-enters the circulation system.

As a critical safety device for drilling operations, the vacuum degasser rapidly processes various types of invading gases, playing a key role in restoring drilling fluid density and stabilizing fluid performance.

To achieve high-efficiency solids control, oilfield solids control systems must follow the graded treatment principle—removing particles by size to avoid overloading small equipment. For example, the shale shaker removes large particles first, enabling desanders and desilters to operate efficiently afterward. With precise functional division and collaborative work, these solids control devices gradually eliminate harmful solids and gases from drilling fluid. They are the key to maintaining drilling fluid performance, reducing downhole accident risks, stabilizing the operation of the entire solids control system, and ensuring smooth oil drilling operations.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li