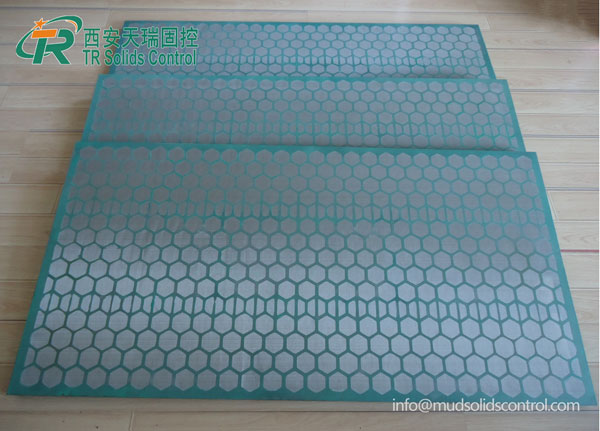

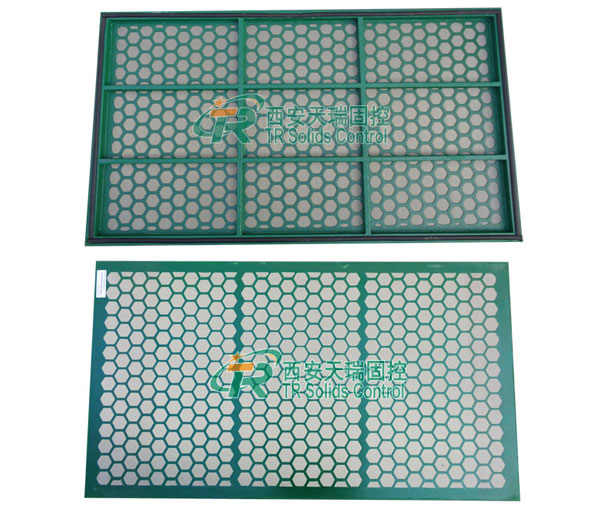

Steel Frame Shaker Screens are critical replacement parts for shale shakers in oil drilling and industrial applications. Their quality directly impacts screening efficiency and equipment service life. To select high-quality Steel Frame Shaker Screens, comprehensive considerations must be given to core structure, material craftsmanship, compatibility, and more. As professional shale shaker screen manufacturer, TR Solids Control has compiled detailed selection criteria based on years of production experience.

The first step in selecting a shaker screen is to clarify the application scenario and compatible equipment requirements. Steel Frame Shaker Screens are mainly used in oil solids control systems, and different working conditions have varying demands for screening precision and load-bearing capacity. Firstly, confirm key specifications such as frame length/width, mesh size, and layer count to ensure perfect compatibility with existing shale shaker equipment. TR Solids Control offers custom frame type oil shale shaker screens in various specifications to effectively solve equipment compatibility challenges.

The frame is the core component supporting the shaker screen, and its strength directly determines the screen’s vibration resistance and service life. High-quality Steel Frame Shaker Screens are welded using high-strength square steel tubes or flat steel, with multiple reinforcing ribs to effectively distribute pressure during vibration and prevent frame deformation or fracture. When selecting, check if the frame welds are firm (no incomplete welding) and if the reinforcing ribs are evenly distributed. TR Solids Control strictly controls the frame welding process to ensure optimal strength, making the screens suitable for long-term high-frequency vibration working conditions.

Mesh Material

The mesh is the functional part of the shaker screen, and its material and weaving process directly affect screening performance and durability. Premium screens use corrosion-resistant and wear-resistant materials such as stainless steel, which can withstand harsh oil drilling environments.

Mesh-Frame Bonding Method

There are two common bonding methods between the mesh and frame: metal backing plate fixation or direct adhesion. Metal backing plate fixation provides a more stable connection, ensuring the mesh does not loosen or fall off during vibration. Direct adhesion uses high-strength bonding technology to ensure tight fit between the mesh and frame. TR Solids Control strictly controls the bonding process and selects the appropriate method based on customer needs and application scenarios to guarantee screen quality.

High-quality Steel Frame Shaker Screens feature user-friendly design details. Each screen is equipped with dedicated rubber plugs for repairing minor mesh damage, extending the screen’s secondary service life and reducing operational costs. When selecting, check for such practical accessories and inquire about after-sales service and quality guarantees. As reliable shale shaker screen manufacturer, TR Solids Control provides not only rubber plugs but also comprehensive after-sales support for peace of mind.

Selecting regular and professional shale shaker screen manufacturer is crucial. TR Solids Control boasts advanced production equipment and complete quality inspection system. From raw material procurement and production processing to finished product testing, every link is strictly controlled to ensure compliance with high-quality standards. We offer custom Steel Frame Shaker Screens tailored to specific customer specifications and application scenarios, delivering optimal performance.

Selecting high-quality Steel Frame Shaker Screens requires comprehensive consideration of working condition compatibility, frame material/structure, mesh quality, repair accessories, manufacturer strength, and custom services. TR Solids Control provides premium frame type shale shaker screens with professional support. For more product information or custom inquiries, contact us today!

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li