The drilling solids control system, also known drilling fluid purification system, is essential equipment for solid-liquid separation and solids control in oil drilling. It enables the recycling of drilling fluid, which not only cuts the cost of waste mud disposal but also minimizes environmental pollution. As a professional manufacturer of mud purification equipment, TR Solids Control has developed comprehensive drilling solids control system tailored to meet the demands of oil drilling projects ranging from 2000 to 7000 meters in depth. Boasting stable performance and high-efficiency purification capabilities, this system has become the preferred equipment for both onshore and offshore drilling operations.

The full set of TIANRUI drilling solids control system is composed of 3 to 7 composite tanks, integrated with multi-stage purification equipment to form full-process purification system. The solids control system consists of variety of devices that work in synergy, including Shale Shaker, sand pump, vacuum degasser, desander, desilter (or mud cleaner), centrifuge, agitator, shear pump, hopper, and mud tank, to achieve efficient purification of drilling fluid.

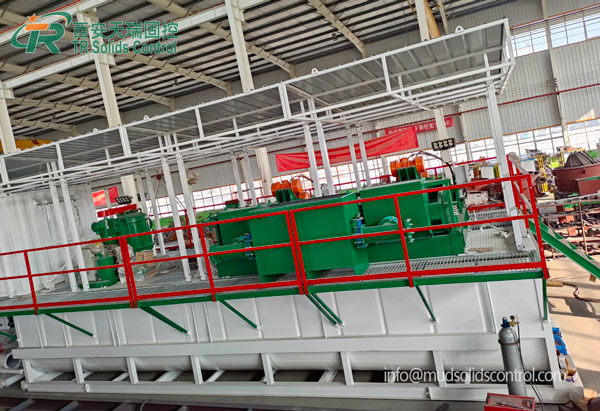

Assembled in TIANRUI's workshop, the drilling fluid solids control system is built on customized tank bodies, where key purification equipment such as Shale Shaker, desander, desilter and centrifuge are installed. The upper part of the drilling fluid tank adopts rectangular structure, with solids control equipment arranged on the tank surface; the lower part is of an arc-shaped structure, where suction and sand cleaning pipelines are laid out. The sand cleaning door and the drilling pump suction port are located at the bottom of tank, enabling full suction and discharge of drilling fluid to meet the zero-discharge requirements of drilling fluid. TIANRUI's solids control system operates reliably under various working conditions, features strong operational capacity, and complies with all design specifications.

Drilling fluid from the wellhead is returned through the return line to the drilling fluid distributor on the Shale Shaker tank. The drilling fluid in the distributor is evenly distributed to the Shale Shaker for treatment, and the processed drilling fluid then flows into the sand settling chamber. After sedimentation in the sand settling chamber, the drilling fluid enters the degassing chamber via the high-level drilling fluid trough. The degasser discharges the treated drilling fluid into the desanding chamber. If the drilling fluid is free from gas invasion, the degasser can be kept out of operation. The degassing chamber is connected to the desanding chamber, allowing direct desanding treatment. The desilter draws drilling fluid from the desilting chamber, and the treated drilling fluid is discharged into the centrifuge chamber. The medium-speed centrifuge sucks in the drilling fluid from the centrifuge chamber, and the processed fluid is transferred to the high-speed centrifuge chamber. The high-speed centrifuge takes in the drilling fluid from the high-speed centrifuge chamber 2; the separated cuttings are discharged outside the tank, while the purified drilling fluid flows into the suction chamber.

TIANRUI's drilling solids control system and supporting mud purification equipment are widely applied in multiple fields, including onshore and offshore oil drilling platforms, natural gas drilling, horizontal directional drilling, trenchless engineering, and construction pile driving. The system is compatible with the treatment requirements of different types of drilling fluids, such as water-based and oil-based drilling fluids.

The system has gained market recognition by virtue of four core values:

High Efficiency & Energy Conservation: It significantly improves the recycling rate of drilling fluid, reducing the procurement cost of new mud and the disposal cost of waste mud by 30%-50%.

Environmental Compliance: It strictly achieves zero discharge of drilling fluid, avoids the risk of soil and water source pollution, and complies with green drilling standards.

Stability & Durability: Key components are made of high-wear-resistant polyurethane materials, suitable for working conditions in various regions with temperatures ranging from -30℃ to 80℃, and the service life of the equipment is significantly longer than that of traditional models.

Strong Adaptability: The number of tanks and equipment configuration can be flexibly customized according to drilling depth and processing capacity, meeting the needs of different drilling projects from 2000 to 7000 meters in depth.

TR Solids Control has deeply engaged in mud purification equipment field for years. With professional technology and reliable quality as the core, we provide customized solids control system solutions for global drilling engineering, helping customers improve drilling efficiency, reduce operational costs, and achieve win-win situation of economic and environmental benefits.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li