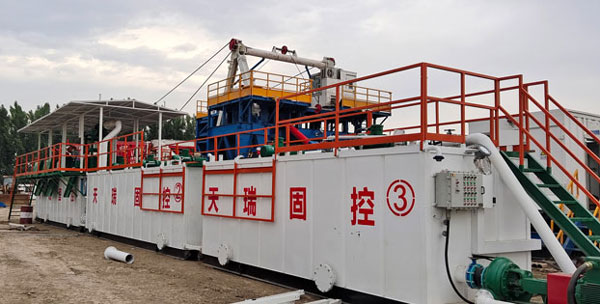

The application value of drilling solids control system ultimately lies in on-site performance. As a critical component for ensuring the safety, improving the efficiency and meeting the environmental standards of drilling operations, the standardized on-site application of TR Solids Control Drilling Mud System (Solids Control System) determines the overall quality and efficiency of drilling projects, and adapts to the actual needs of various complex drilling scenarios.

Based on the geological conditions and mud types of different drilling blocks, TR Solids Control optimizes the configuration of the mud solids control system by integrating core equipment including shale shakers, desanders, sand pumps, agitators and centrifuges. It conducts real-time monitoring and adjustment of process parameters to achieve drilling mud recycling and reduced emissions, which not only lowers operational costs but also complies with environmental protection requirements.

During drilling operations, improper treatment of drilling waste such as oily sludge and cuttings will not only cause soil and water pollution and trigger environmental risks, but also clog equipment, affect drilling progress and increase construction costs. TR Solids Control Drilling Mud System effectively removes various impurities in drilling fluid through multi-stage purification treatment, enhances the performance stability of drilling fluid, ensures the quality of drilling construction, reduces mud consumption and the pressure of waste treatment, and achieves a win-win situation of economic benefits and environmental protection.

Pre-construction preparation and equipment commissioning are the primary prerequisites for on-site application, laying the foundation for the stable operation of the system. Before operation, it is necessary to set the equipment parameters of the treatment system in accordance with the geological characteristics of the drilling block (such as cutting composition and formation complexity) and the type of drilling fluid. Meanwhile, the integrity of equipment should be inspected to ensure that the shale shaker screens are free from damage, the vibration frequency meets the standard, the centrifuge speed is normal, and the pipelines of the chemical dosing system are unobstructed without blockage. In addition, a dedicated temporary storage area for drilling waste should be demarcated with anti-seepage and anti-loss measures to eliminate secondary pollution during the pre-treatment stage. During the commissioning stage, no-load trial operation should be carried out to identify potential operational hazards of all equipment, ensuring the system can be put into stable use after startup.

The treatment effect of solids control system depends on the standardized operation of the mud treatment process, which must strictly follow the principle of "classified treatment and precise regulation".

Solid-liquid separation: Large particle cuttings in the drilling fluid are removed by the shale shaker. During operation, the interception status of the shaker screens should be observed in real time. If problems such as mud loss or screen blockage occur, the shaker screens should be replaced or the vibration frequency adjusted in timely manner to ensure separation efficiency. The mud treated by the shale shaker is sent to desanders and desilters for secondary fine separation to further remove fine sand particles and impurities, obtaining refined drilling fluid.

Centrifugal dehydration: The mud after secondary separation is fed into the centrifuge, and the feed flow rate must be strictly controlled within the rated range of the equipment to avoid the decline of dehydration efficiency and the increase of energy consumption caused by equipment overload.

Chemical conditioning: According to the oil content and impurity content of drilling waste, demulsifiers, flocculants and other chemicals are accurately dosed to ensure the full reaction between chemicals and waste, improving the effect of subsequent purification treatment.

During the on-site application, attention should be paid to the handling of faults and the management of safety and environmental protection. Through standardized management and precise operation, the on-site application of TR Solids Control Drilling Mud System gives full play to equipment efficiency, realizes the efficient, safe, environmentally friendly and low-cost progress of drilling operations, and boosts the green and sustainable development of the drilling industry.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li