In recent years, corrosion-resistant mud shale shaker screens have become "standard configuration" in drilling fluid processing systems, due to to their outstanding performance in improving drilling efficiency and reducing costs. Though seemingly insignificant in the oil drilling industry, mud shale shaker screens play crucial role in the overall drilling efficiency and operational costs. The high-quality corrosion-resistant screen can significantly enhance solid-liquid separation efficiency and minimize downtime; while inferior screens may cause mud leakage, poor screening results, or even equipment failures. So, how to select a truly reliable corrosion-resistant mud shale shaker screen?

The material of shaker screen directly determines its corrosion resistance, service life, and operational stability—especially in the complex acid-alkaline mud environment of oil drilling. With decades of experience in the oil industry, TR Solids Control adopts 304 or 316 stainless steel, processed through special heat treatment technology, endowing the screen with both high strength and fatigue resistance. It maintains structural integrity even under long-term high-frequency vibration, effectively resisting chemical corrosion from mud, and its wear resistance is increased by over 50% compared to ordinary materials.

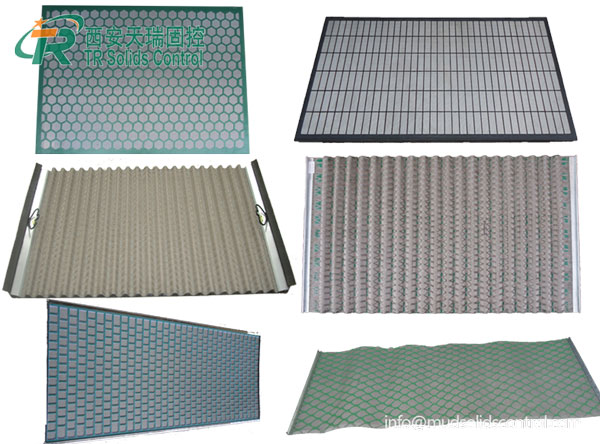

Different drilling conditions have varying requirements for screening precision and adaptability. Thus, it’s essential to select the appropriate hole type and specification based on actual needs. TR Solids Control offers wide range of hole types (including square, rectangular, etc.) and screen sizes (covering 20 to 400 mesh). Each shaker screen undergoes multiple tension tests and laser leveling inspections, effectively avoiding uneven screening and local excessive wear caused by an uneven screen surface. Tianrui’s screens are suitable for various harsh conditions such as shale gas development and deep well drilling, enabling efficient separation of solid particles. Choose the right hole type and size according to your specific drilling scenario.

The weaving technology of shaker screen directly affects screening precision, efficiency, and impact resistance. TR Solids Control adopts advanced plain weave and twill weave technologies to ensure uniform mesh size, no deformation, and no burrs. The precision structural design allows the screen to maintain stable filtration performance even under high-pressure mud impact, separating solid particles of different particle sizes, improving mud recovery rate, and reducing drilling fluid loss costs.

Screen clogging is common challenge in drilling operations, which significantly reduces work efficiency. TR Solids Control’s screens feature unique 3D three-dimensional structure design combined with reasonable open area, significantly enhancing particle passing capacity and fundamentally reducing clogging. Meanwhile, special surface treatment technology further reduces mud adhesion, facilitating mud flow and maintaining stable screening efficiency.

Different shale shaker equipment and drilling conditions require screens of different specifications. TR Solids Control provides professional custom sizing services, precisely matching mainstream domestic and international shale shaker brands and models. Before purchasing, please confirm key parameters such as equipment specifications, screen size, and hook edge type to ensure compatibility—avoiding installation difficulties or poor sealing due to mismatched sizes. Tianrui’s customized services meet the personalized needs of different customers and enhance screen performance.

The high-quality corrosion-resistant mud shale shaker screen is vital guarantee for efficient and safe drilling operations. Choosing the right product is key to truly achieving cost reduction and efficiency improvement. With premium materials, exquisite craftsmanship, precise compatibility, and thoughtful custom services, TR Solids Control has become the preferred partner for numerous drilling companies. For more details on screen products or custom solutions, feel free to contact us for consultation.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li