Linear shale shakers are preferred choice for oilfields. Especially for large-scale material processing in oil drilling, mining, chemical engineering and other industries, high-capacity linear shale shakers are required. So how to select high-capacity shale shaker model? TR Solids Control's TRZS series shale shakers help you analyze and provide solutions based on technical parameters, structural design, working condition adaptability and other factors.

The function of shale shaker is to maximize the separation of drill cuttings from solid-liquid mixtures in accordance with matched working condition requirements, enhance the performance and utilization rate of drilling fluid, and ensure stable operation.

Whenever customers inquire, we always first understand the drilling working conditions—such as the operating environment, material properties, and other factors—to provide suitable and cost-effective shale shaker products.

Clarify Processing Capacity

Calculate the required processing capacity for equipment selection based on the customer's actual needs. For example, if a drilling operation requires handling 80m³ of drilling fluid per hour, equipment with a rated processing capacity of ≥100m³/h should be selected.

Clarify Material Properties and Screening Requirements

Material Types: Oil drilling fluid (high viscosity, containing drill cuttings), ore raw materials (dry particles), chemical raw materials (corrosive). Tianrui has customized special models with adhesion resistance and corrosion protection for the drilling fluid scenario.

Screening Precision: The size of solid particles to be separated determines the selection of screen mesh size (Tianrui supports customization of 0.1-5mm mesh sizes; for high-capacity scenarios, wedge wire screens are optional, offering better anti-clogging performance).

Material Temperature/Corrosiveness: For high-temperature (>60℃) or corrosive materials, high-temperature resistant motors and stainless steel/special-coated screen boxes are required.

Clarify Operating Environment

Installation Space: Confirm the length, width and height constraints of the site (e.g., for drilling platforms with limited space, Tianrui's modular-design products are optional, featuring detachable and easy relocation).

Environmental Conditions: Outdoor/downhole, high temperature and humidity/dusty/flammable and explosive (drilling sites require explosion-proof design; Tianrui equipment complies with API standards and ATEX explosion-proof certification).

Power Supply Conditions: Confirm the voltage (380V/660V) and frequency (50Hz/60Hz) to avoid mismatching between the motor and power supply.

Screen Area

Screen surface size directly determines processing capacity. A multi-layer screen mesh design is also available to increase the total screen mesh area. The aspect ratio of the screen surface should be controlled between 2.5-3.5:1, which balances material residence time and screening efficiency—avoiding clogging caused by excessive length and insufficient screening due to excessive shortness.

TR Solids Control’s TRZS584 model boasts a processing capacity of 130m³/h and a screen mesh area of 2.7m², making it suitable for medium and large-scale drilling operations.

Vibration Parameters

Linear motion (dual-motor synchronous operation) with a vibration frequency of 1800–2800 RPM and amplitude of 4–8 mm balances screening efficiency and screen mesh service life.

Vibration frequency and amplitude directly affect screening efficiency. The TRZS584 model features an amplitude of 7 mm and vibration intensity of 7.0G; the exciting force can be further adjusted by modifying the angle of the eccentric blocks to adapt to the fluidity of different materials.

Tianrui’s adjustable eccentric block design allows personalized setting of frequency and amplitude based on the properties of drilling cuttings, enabling more effective separation of particles as small as 75 μm.

Motor Power

The motor serves as the power guarantee for the shale shaker’s processing capacity. Tianrui adopts foreign-brand motors (IP55 protection class) to ensure continuous operation.

The TRZS584 model is equipped with dual motors (1.5kW×2) with a total power of 3kW, making it suitable for continuous high-load operation. When the processing capacity is close to the equipment’s upper limit, it is recommended to select a higher-power model to prevent motor overheating.

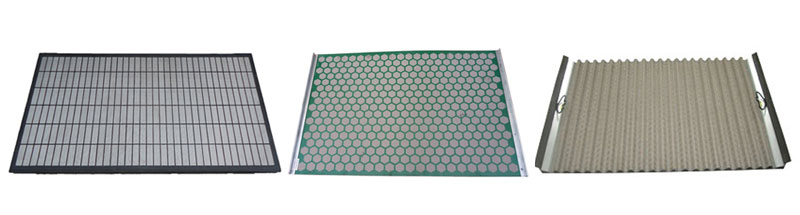

Screen Material

For wear resistance requirements (e.g., drilling cuttings, ore): Polyurethane screens (wear life 3-5 times longer than ordinary metal screens) or stainless steel wedge wire screens (uniform pore size, anti-clogging).

For corrosion resistance requirements (e.g., oil-based drilling fluid, chemical materials): Select 316L stainless steel screens + anti-corrosion coating.

For mesh size requirements: Tianrui offers 10-400 mesh options; multi-layer screen mesh structure is available for high-capacity scenarios.

Shaker screen tensioning method: Ensures uniform screen tension, reducing clogging and screen damage. The TRZS584 adopts a wedge-type clamping device, enabling single-screen replacement time of less than 5 minutes while maintaining stable tension.

Screen Box Structure: Impact Resistance & Fatigue Resistance

Material: Thickened steel plate welding + integral annealing treatment (Tianrui’s screen box adopts 10mm thickened Q345 steel plates, with vibration fatigue strength increased by 40%), avoiding deformation or cracking under high-capacity operation.

Sealing Design: Fully sealed screen boxes are required for scenarios involving drilling fluid, chemical materials, etc. (Tianrui uses rubber sealing strips + leak-proof frames to prevent material leakage and environmental pollution).

Shock Absorption Device: High-capacity equipment generates significant vibration impact and requires heavy-duty shock absorption springs (Tianrui adopts rubber + steel spring composite shock absorption, reducing vibration transmission to the ground and protecting the installation foundation).

Feed and Discharge Design

Feed Inlet: Adopts wide-caliber + deflector design (the width of Tianrui’s feed inlet is consistent with the screen surface, and the angle-adjustable deflector avoids concentrated material accumulation on one side of the screen).

Discharge Outlet: Customizable according to the height of subsequent equipment (e.g., adapting to the desander feed inlet of the solids control system in drilling scenarios), preventing material overflow caused by unsmooth discharge.

Modularity and Maintainability

High-capacity equipment requires frequent maintenance; modular design is optional (screen box, motor, and shaker screen can be quickly disassembled and replaced). Wear parts (such as shock absorption springs and sealing strips) feature high versatility and easy procurement.

Quick-Release Shaker Screen Structure: The wedge-type clamping device shortens shaker screen replacement time, minimizing operational disruption.

IV. Tianrui TRZS584 Linear Shale Shaker

| Parameter | Reference Values | Impact on Processing Capacity |

| Capacity | 130m³/h | Baseline Processing Capacity: Suitable for Medium-Scale Drilling Operations |

| Screen size | 585×1165mm×4 sheets | Total Screen Area: 2.7m²; screen surface width determines the upper limit of processing capacity. |

| Vibration intensity | 7.0G (Adjustable) | High G-force improves material penetration capacity, enhancing processing efficiency. |

| Amplitude | 7mm | Large amplitude improves material conveying speed, reducing screen mesh clogging. |

| Motor Power | 1.5kW×2 (Dual-Motor) | Provides stable vibration energy to ensure meeting the demand for high processing capacity. |

| Screen Box Angle | -3° to +5° (adjustable) | Affects material flow rate: The larger the screen surface angle, the higher the processing capacity. |

Advantages of TRZS584 Shale Shaker:

High G-force Design (7.0G): Effectively overcomes the adhesive force of high-viscosity drilling fluid, improving solid separation efficiency.

Large Amplitude (7mm): Accelerates material movement, ideal for high-solid-content drilling fluids.

Four Parallel Screens: Increases effective screening area, boosting overall processing capacity.

Dual-Motor Synchronous Drive: Delivers stable vibration energy, ensuring smooth operation at high capacity.

Compliance Certification: Meets API standards, explosion-proof and environmental requirements.

To select high-capacity shale shaker model, please consult Tianrui's technical team to evaluate your specific drilling conditions (displacement, drilling cutting type, environment) and obtain a customized solution. A suitable high-capacity linear shale shaker can improve drilling efficiency, reduce fluid loss, and maximize project profitability.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li