The desander is a secondary treatment device in the drilling fluid solids control system. It mainly separates medium and coarse solid particles (such as sand and rock cuttings) with a particle size of 44-150 micrometers from the drilling fluid, reducing the processing load on subsequent desilters and centrifuges.

The drilling fluid desander uses centrifugal separation technology. The mud containing solid phase enters the hydrocyclone tangentially. The high-speed rotation generates centrifugal force, and the denser solid phase particles are thrown against the wall of the device and spiral downwards, and are discharged from the bottom outlet (sand discharge port). The cleaner liquid phase and fine particles are discharged from the top overflow pipe and enter the next stage of treatment.

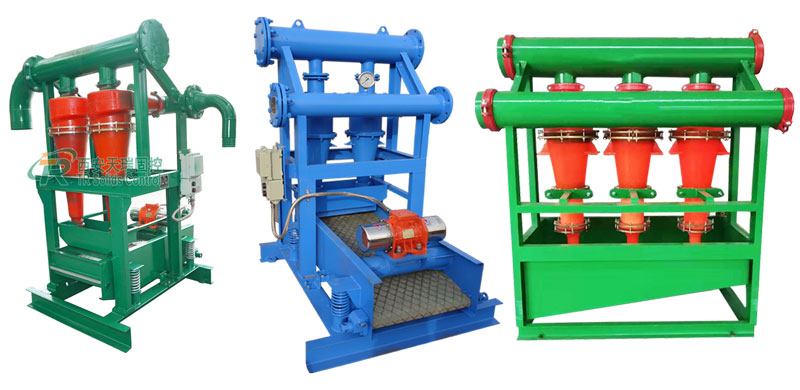

cyclone

Material: High wear-resistant polyurethane (life up to 4200 hours) or high chromium cast iron (life 2000 hours).

Specifications: Commonly used are 8-inch, 10-inch, and 12-inch, which can be flexibly combined according to the processing capacity (the processing capacity of a single 6-inch hydrocyclone is ≥80m³/h).

Advantages: Polyurethane material has excellent wear resistance and a lifespan more than 3 times that of ordinary rubber; the clamp-type quick-installation structure reduces replacement time to within 15 minutes.

Bottom flow shale shaker(Optional):High manganese steel + wear-resistant screen; recovers useful solid phase from underflow; improves drilling fluid economy and reduces material waste.

sand pump:Wear-resistant alloy; provides the power for conveying mud into the hydrocyclone; working pressure 0.2~0.4MPa, flow rate depends on the model.

hydrocyclone liner:Made of polyurethane, it is wear-resistant, corrosion-resistant, and has a long service life, making it a vulnerable part.

Import/Export Flanges:Standard DN125/DN150, for connecting piping systems.

Sand discharge port assembly:It includes a sand discharge valve and connecting pipes to control the discharge of solid phase.

Pressure gauges and valves:Monitor the pressure and adjust the flow rate to ensure the equipment operates within the 0.15~0.35MPa range.

Stands and bases:Support equipment ensures stability and facilitates installation and maintenance.

Taking the TRCS series as an example:

| Model | Capacity (m³/h) | Cyclone Specs | Cyclone Qty | Separation size (μm) | Work pressure (MPa) |

| TRCS200-1S/2S | 60/120 | 8 inches(DN200) | 1/2 | 45-75 | 0.25-0.4 |

| TRCS250-2S | 120/240 | 10 inches(DN250) | 2 | 45-75 | 0.25-0.4 |

| TRCS300-1S/2S | 140/280 | 12 inches(DN300) | 1/2 | 45-75 | 0.25-0.4 |

Accessories Configuration:

Underflow screen: TRTS60 (60 mesh) or TRZS752 (75 mesh).

Inlet/outlet diameter: DN125mm-DN200mm, suitable for different flow requirements.

Modular design: The number of hydrocyclones can be configured as needed to adapt to different drilling scales. For example, 8-inch, 10-inch, and 12-inch hydrocyclones can be flexibly configured according to the processing capacity requirements, with a single unit processing capacity covering 60-280 m³/h.

Superior Material: The hydrocyclone is made of highly wear-resistant polyurethane, which is 10 times more wear-resistant than ordinary steel and has a lifespan that is 3-5 times longer.

Intelligent monitoring: Equipped with an electrical control cabinet, built-in sensors monitor pressure and flow in real time and automatically adjust the working status.

Compact structure: Small footprint, easy to transport and install, suitable for land/offshore drilling platforms.

Application Scenarios - Solid Control Experts in Multiple Fields

Oil and gas drilling: mud purification for conventional wells, deep wells, and ultra-deep wells

Trenchless engineering: Horizontal directional drilling (HDD), tunnel boring machine (TBM) construction, mud recovery for piling projects

Gas reservoir exploration: Protecting high-pressure drilling equipment and reducing maintenance costs

Other areas: river dredging, geothermal drilling, industrial wastewater treatment

Why choose TR Desander?

Four core advantages:

Highly efficient separation: It can remove 95% of solid particles larger than 74μm and 50% larger than 40μm, with a separation efficiency of over 90%.

Extra-long lifespan:

The wear resistance of the hydrocyclone is improved by 50%, and its service life is more than 3 times that of ordinary products.

Reduce downtime for maintenance and improve drilling efficiency

Highly adaptable:

Compatible with different drilling fluid systems (water-based, oil-based)

To meet the solids control needs of different formations (sand, mudstone, shale).

Full lifecycle service:

API Certification Quality Assurance

Services in 60+ countries worldwide

Customized solutions (including installation, commissioning, and training)

Note: TR Solids Control provides complete solids control system solutions, and can customize "Desander - Desilter - Shale shaker" integrated machine (TRZJ series), which reduces the footprint by 30%, makes operation more convenient, and increases efficiency by 20%, meeting the needs of different drilling scales.

TR Solids Control's TRCS series desanders are core equipment in drilling fluid solids control systems. They utilize efficient centrifugal separation technology to protect drilling equipment, stabilize mud performance, and reduce operating costs. Choosing high-quality desanders and accessories, and performing regular maintenance, are crucial for ensuring efficient, economical, and environmentally friendly drilling operations.

Selection Recommendation: Select a desander of appropriate specifications based on the drilling scale, mud properties, and processing volume requirements. Prioritize products from professional manufacturers such as TR Solids Control to obtain more reliable quality and comprehensive after-sales service.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li