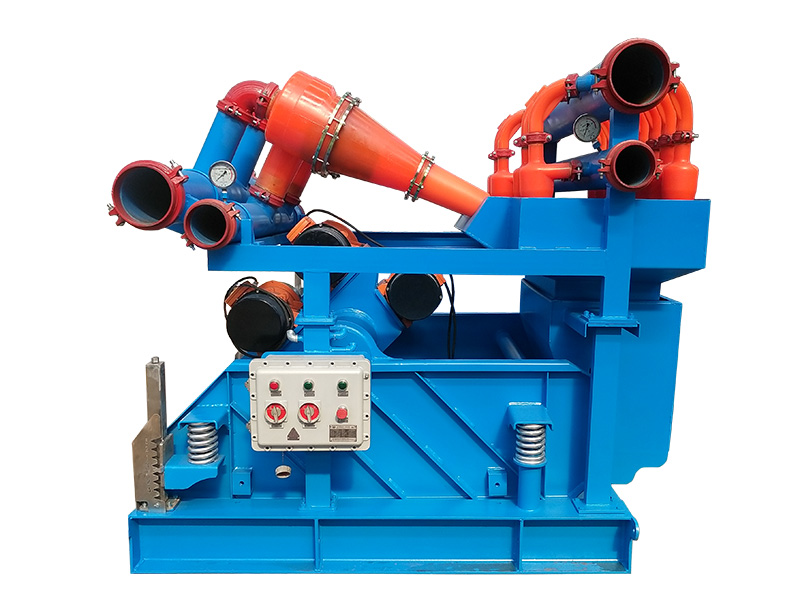

TR Solids Control's TRQJ series mud cleaners (also known as Desander Desilter machines) are secondary and tertiary treatment devices in drilling fluid solids control systems. They consist of three main parts: desander, desilter, and underflow shale shaker, achieving efficient removal of harmful solid phases (20-74μm) from drilling fluids. Accessories for mud cleaner are also crucial. As solids control equipment manufacturer, TR Solids Control provides the following accessory list:

Shale Shaker Components

Screen box assembly: TRZS series shale shaker (such as TRZS60)

Shaker Screen: Stainless steel / polyurethane material, various sizes (e.g., 1800×600mm, 140 mesh / 40 mesh)

Vibration motor: Explosion-proof type, power 0.5-5.5kW, speed 1445r/min

Vibration beam: Transmits vibration force to ensure efficient screen separation.

Screen box angle adjustment device: Adjusts the tilt angle of the screen surface to optimize processing efficiency.

Screen fixing device: plate tensioning or wedge block fixing system

Desander Component

Desander hydrocyclones: TRQJ series standard configuration is 250mm diameter, quantity 1-2 units (TRQJ250×2S).

Hydrocyclone cone: made of polyurethane or high-chromium cast iron, wear-resistant and durable.

Underflow nozzle: Adjustable to control underflow discharge.

Slurry distributor: evenly distributes slurry to each hydrocyclone.

Pressure gauge: Monitors working pressure (normal range 0.25-0.4 MPa)

Desilter Component

Desilter hydrocyclones: 100mm diameter, 4-12 units (e.g., TRQJ100×12N).

Hydrocyclone assembly: Multiple 4-inch desliming cones (4″×12 or 4″×16)

Overflow pipe: Connects the hydrocyclone and the vibrating screen to discharge the purified liquid.

Underflow regulating device: controls the underflow discharge state to be umbrella-shaped spray.

Sand Pump Assembly (slurry supply system)

Centrifugal sand pump: Provides slurry pressure with flow rate up to 240 m³/h

Pump casing: made of wear-resistant material (such as ductile iron), corrosion resistant

Impeller: A wear part that needs to be replaced regularly.

Mechanical seal: Prevents mud leakage and extends pump life.

Coupling: Connects the motor and pump shaft, transmitting power.

Motor: Explosion-proof, power 15-30kW, IP55 protection rating

Pipes and Fittings

High-pressure hose: connects pump and hydrocyclone, resistant to high pressure (0.25-0.4MPa)

Elbows/Tees: Change the flow direction and connect various components.

Clamps: 6 inch / 8 inch, for quick connection of hydrocyclones for easy maintenance.

Ball valve: Controls the number of each hydrocyclone in operation, facilitating maintenance.

Structural Supports

Base frame: Overall support structure to ensure equipment stability

Support frame: Supports the vibrating screen and hydrocyclone assembly

Vibration damping devices: reduce vibration transmission and protect the foundation.

Control System

Electrical control box: Explosion-proof type, controls motor start/stop and monitors...

Overload protection device: Prevents motor damage due to overload.

Pressure gauge: Monitors pump outlet and hydrocyclone pressure

Sensors: Monitor parameters such as liquid level and flow rate (some high-end models)

| Accessory name | Replacement cycle | Material | Remark |

| Screen | Depends on the working conditions | Stainless steel / polyurethane | High-frequency vibration is prone to wear |

| Hydrocyclone underrunner | 200-500 hours | Polyurethane | Direct contact with solid particles |

| sand pump impeller | 500-1000 hours | Wear resistant alloy | scouring by high-speed mud |

| mechanical seal | 800-1200 hours | Tungsten carbide / ceramics | Prevent mud leakage |

| O-ring | Regular inspection and replacement | Rubber / Fluororubber | Sealing connection parts |

Taking TRQJ250×2S-100×12N as an example:

Desander hydrocyclones: 2 x 250mm diameter

Desilter hydrocyclones: 12 x 100mm diameter

Underflow vibrating screen: TRZS series

Processing capacity: Approximately 240 m³/h

Operating pressure: 0.25-0.4 MPa

Matching sand pumps: 1-2 units (depending on model)

Mud Cleaners are key equipment in drilling solids control systems. TR Solids Control's TRQJ series efficiently removes harmful solid phases from drilling fluids through a perfect combination of Desander and Desilter and a shale shaker. Understanding its component composition helps with equipment maintenance and troubleshooting, extending equipment lifespan. For more detailed component models or technical parameters, it is recommended to contact TR Solids Control's official website (Xi'an TR Petroleum Machinery Equipment Co., Ltd.) directly to obtain an original parts list.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li