Xi'an Tianrui Petroleum Machinery Equipment Co., Ltd. (TR Solids Control) is a domestic enterprise specializing in the research and development and manufacturing of oilfield mud recovery and purification equipment. Founded in 2010 and headquartered in Xi'an, Shaanxi Province, the company focuses on providing comprehensive mud treatment solutions for oil and gas drilling, trenchless engineering, and building piling.

TR Solids Control's independently developed mud recycling system employs multi-stage solid-liquid separation technology to achieve efficient removal and recycling of solid particles in drilling fluid. Specifically designed for oilfield drilling scenarios, the system combines a mud vibrating screen, desander, desilter, and centrifuge to separate drill cuttings from the mud to below 25 microns, ensuring the mud's performance meets reuse requirements and significantly reducing drilling fluid consumption costs. The system also supports modular design, adapting to different onshore and offshore operating environments.

TR Solids Control provides a full range of oilfield mud recovery and purification equipment, covering the entire process from primary separation to fine purification:

Level 1 solids control equipment:

Shale shaker: Adopts a composite motion trajectory design of linear and elliptical motion, with G-value steplessly adjustable from 0.5 to 6.5, and a processing capacity of 200-500 m³/h. The TRZS series is equipped with a three-layer polyurethane composite screen (API 20-325 mesh), which has a service life three times longer than traditional metal screens and is suitable for high-viscosity mud treatment in shale gas horizontal wells.

Level 2 solids control equipment:

Desander: 6-12 inch cone design, processing capacity 150-300m³/h, separation accuracy 44-74μm, lined with silicon carbide composite material, lifespan over 2000 hours.

Desilter: 2-5 inch cone design, processing capacity 50-150 m³/h, separation accuracy 15-44 μm, can be integrated into mud cleaner to achieve barite recovery.

Desander Desilter All-in-one machine(Mud Cleaner): integrates 3 sand removal hydrocyclones and 16 mud removal hydrocyclones to adapt to the changes in solid content of different strata.

Level 3 solids control equipment:

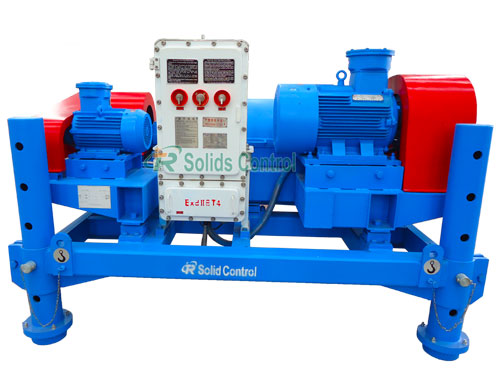

Decanter centrifuge: Medium-speed centrifuge (TRLW355-450 series) with a speed of 1800-2500r/min, a throughput of 40-60m³/h, and a solid phase recovery rate of up to 95%. The drum is made of 2205 double-sided stainless steel centrifugal casting, which extends the service life by 50%.

High-speed centrifuge (TRLW600 series): speed 3000-5000r/min, separation accuracy 2-7μm, equipped with a fully hydraulic differential speed adjustment system to automatically adapt to changes in slurry viscosity.

Auxiliary equipment:

Vacuum degasser: TRZCQ series has a processing capacity of 240-360 m³/h and a vacuum degree of -0.04 to -0.08 MPa. It can remove more than 95% of free gas and some dissolved gas from the mud. It is equipped with an intelligent gas-liquid separator and the explosion-proof control cabinet meets the ATEX standard.

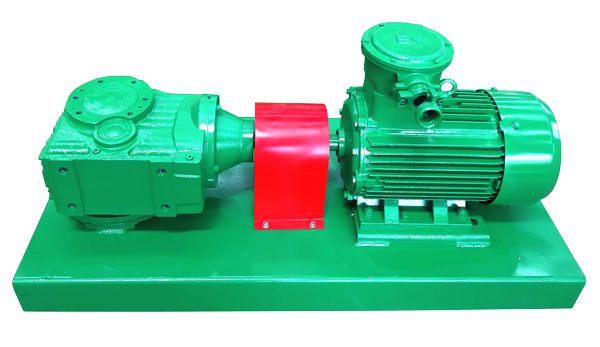

Mud mixer: Direct drive design without coupling, power 5.5-37kW, equipped with frequency conversion control system, solid phase suspension rate maintained above 98%.

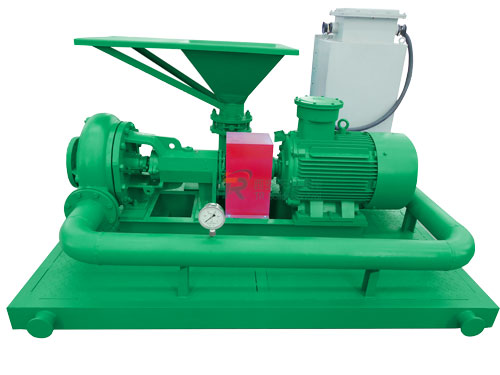

Jet mixing device: Utilizes the Venturi effect to achieve rapid mixing of bentonite and barite, with a mixing efficiency 3 times higher than traditional mixing, increasing the slurry density from 1.0 g/cm³ to 1.6 g/cm³ within 10 minutes.

Modular mud tank: with a volume of 50-300m³, it adopts a conical bottom structure and an edge mixing system to reduce dead sand corners. The optimized design of the internal flow channel reduces the mud circulation resistance by 15%.

The solids control equipment's centrifugal sand pumps are made of alloy cast iron and use SKF bearings. They are interchangeable with international brand Mission pumps and feature wear resistance, corrosion resistance, and high head. They have also passed the American Petroleum Institute (API) certification. In addition, the company offers a mud purification system for trenchless engineering, capable of handling high-concentration mud generated during directional drilling and pipe jacking, with a processing capacity of 60 m³/h. The oil-based/water-based mud-free system adopts a modular design to achieve reduced drilling waste treatment and supports technical solutions such as fracturing flowback fluid treatment and oily sludge treatment.

As a supplier of materials to CNPC, the company is deeply involved in the project construction of major oilfields in China, while expanding into overseas markets through the "Belt and Road" initiative. Its products are already operating stably in drilling projects in Turkmenistan, Australia and other regions.

TR Solids Control has passed ISO9001 quality management system and ISO14001 environmental management system certifications. Its core products, such as mud centrifugal pumps and solids control systems, have obtained international certifications such as API Spec 8A and API Spec 16A, ensuring that the products meet global petroleum industry standards.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li