In current oilfield drilling operations, solids control systems are becoming increasingly important as a key component in ensuring drilling fluid performance, improving drilling efficiency, and protecting the environment.

The integrated oilfield drilling solids control equipment solution is systematic technical solution for purifying and managing drilling fluid (mud) during the drilling process. By integrating multi-stage solid-liquid separation equipment, intelligent control systems, and environmentally friendly processes, it achieves efficient recycling of drilling fluid, optimizes costs, and protects the environment. This solution is widely used in onshore and offshore drilling, deep and ultra-deep wells, and horizontal directional drilling (HDD), and is one of the core supporting technologies for modern drilling projects.

Mud separation equipment

Primary separation: Shale Shaker (mud vibrating screen)

Function: High-frequency vibrating screens quickly separate large rock fragments (>74μm) from drilling fluid, preventing them from entering downstream equipment and causing wear or blockage.

Features: Multi-layer screen design with adjustable separation size; explosion-proof motor drive for adaptability to harsh operating conditions; modular construction for quick screen replacement.

Secondary separation: hydrocyclone (desander/desilter)

Desander: Separates sand particles (40-74μm), protecting the drill bit and drill string from wear.

Desilter: Further removes fine particles (15-40μm), improving drilling fluid cleanliness.

Features: Centrifugal separation for high efficiency; can be used in parallel or series, flexibly adapting to different operating conditions.

Three-stage separation: decanter centrifuge

Function: High-speed rotation separates ultrafine particles (<15μm) and colloidal materials, producing low-solids drilling fluid and achieving high recovery rates.

Features: Adjustable differential speed to accommodate varying mud properties; fully enclosed design prevents secondary contamination.

Mud conditioning system

Vacuum degasser: removes harmful gases from drilling fluid to prevent well kicks or blowouts.

Shear pump/mixer: evenly add chemicals (such as fluid loss reducers, viscosity enhancers) to maintain stable mud properties.

Circulation tank and conveying system

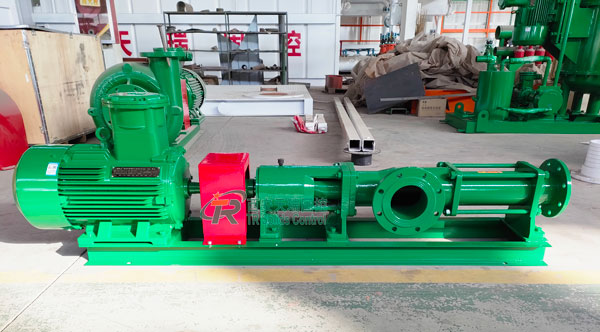

Multi-compartment mud tanks: Separately store clean mud, waste mud, and transition fluid, supporting closed-loop circulation.Centrifugal pumps/screw pumps: Efficiently transport mud, reducing pressure drop and energy consumption.

Improve drilling efficiency

Clean mud reduces drill bit friction and reduces the risk of sticking.

Stabilizes mud properties (density, viscosity, and cutting force) to optimize drilling speed and footage.

Significant cost reductions

Mud recovery rates reach up to 95%, reducing fresh mud purchases by 40%-60%. Waste volume is reduced by over 50%, reducing transportation and disposal costs.

Environmental Compliance

The closed-loop system prevents slurry leakage and meets international environmental standards (such as OSPAR and EPA).

Rock cuttings can be dried and reused (e.g., in brickmaking and road paving).

Intelligent Management

Real-time monitoring of mud parameters (solids content, flow rate, and pressure) and automatic adjustment of equipment operation. Equipment start/stop and parameter adjustment can be performed via PLC or mobile app, ensuring personnel safety.

Land Drilling

Adaptable to extreme environments such as deserts, plateaus, and frozen soil, the equipment is designed to withstand high and low temperatures and resist sand and dust.

Offshore drilling platform

Compact modular design saves space;Corrosion-resistant materials resist seawater erosion.

Deep/ultra-deep well drilling

High-pressure centrifuges and high-temperature cyclones are used to process high-temperature and high-pressure mud.

Horizontal Directional Drilling (HDD)

Low-friction mud formula reduces pipe drag and improves drilling accuracy.

Project Background: A deep well drilling project in an oilfield faced high mud costs, slow drilling rates, and difficult waste disposal.

Deployed an integrated solids control system, including:

4-deck vibrating screen + dual 10-inch desanders + 12-inch desilter; High-speed decanter centrifuge (3200 rpm).

Results:

Mud recovery rate increased from 65% to 92%; Drilling rate increased by 25%, reducing the well cycle by 18 days; Waste disposal costs decreased by 55%.

The integrated solution for oilfield drilling solids control equipment leverages three-in-one model of "equipment integration + intelligent control + environmentally friendly processes" to provide efficient, economical, and sustainable technical support for drilling projects. As oil and gas exploration expands into deep-earth and deep-sea areas, this solution will become a key tool for ensuring drilling safety and enhancing industry competitiveness.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li