As industries like oil drilling, mining, and construction continue to evolve, mud shale shakers—critical for solid-liquid separation—are undergoing rapid technological advancements. This guide outlines 2025 market trends and essential factors to consider when purchasing mud shale shaker.

Remote Monitoring & Predictive Maintenance:

Modern shakers are equipped with IoT sensors to track vibration frequency, screen tension, and fluid flow in real time.

AI-driven analytics predict equipment failures 30 days in advance, reducing downtime by up to 40%.

Example: High-tech brands like Derrick and TR Solids Control .

Self-Adjusting Parameters:

Advanced shakers automatically optimize vibration intensity and screen angle based on mud viscosity and particle size, improving efficiency by 15–20%.

Lower Power Consumption:

New-generation motors reduce energy use by 25% compared to 2020 models, aligning with global carbon neutrality goals.

Some shakers incorporate regenerative braking systems to recover kinetic energy during operation.

Noise Reduction:

Industry-standard noise levels drop from 85–110 dB to ≤80 dB, meeting OSHA and EU workplace safety regulations.

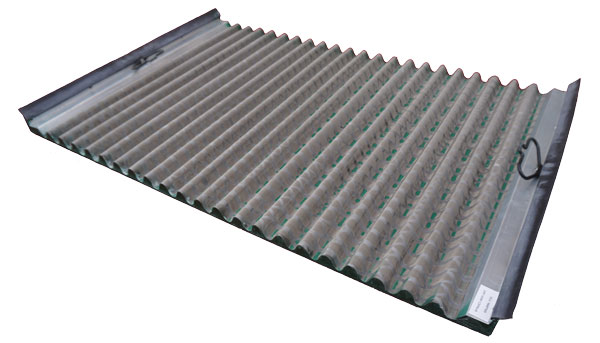

Quick-Change Screens:

Frame-type shakers now feature tool-free screen replacement, cutting downtime from 2 hours to under 10 minutes.

Composite screens (polyurethane + steel) offer 3x longer lifespan than traditional metal screens.

Industry-Specific Solutions:

Oil & Gas: Corrosion-resistant shakers (e.g., TR) withstand H₂S/CO₂ environments, extending service life to 3,000+ operating hours.

Mining: High-capacity shakers handle 500+ t/h of abrasive slurry.

Southeast Asia Infrastructure Boom:

Rising construction projects drive demand for affordable, high-throughput shakers.

Battery Materials Processing:

Lithium extraction requires ultra-fine screening (≤0.074mm), spurring innovation in high-frequency vibrating screens.

Flow Rate (GPM/m³/h):

Small drilling rigs: 100–300 GPM (400–1,200 m³/h).

Large mining plants: 1,000+ GPM (4,000+ m³/h).

Match shaker capacity to your operation’s output. For example:

Vibration Frequency:

Low-frequency (800–1,200 RPM): Best for coarse particles (>2mm).

High-frequency (1,500–3,000 RPM): Ideal for fine particles (<0.5mm).

| Material | Pros | Cons | Best For |

|---|---|---|---|

| 304/316 SS | Corrosion-resistant, long lifespan | Higher cost (20–30% premium) | Oil & gas, chemical plants |

| Polyurethane (PU) | Wear-resistant, quiet operation | Less heat-resistant | Mining, sand processing |

| Composite | Balances cost & durability | Limited high-temp applications | General-purpose use |

| Brand | Strengths | Warranty & Service | Price Range (USD) |

|---|---|---|---|

| Derrick | Ultra-fine screening, low maintenance | 5-year motor warranty, global support | 15,000–40,000+ |

| TR Solids | Cost-effective, modular designs | 3-year warranty, 24/7 tech support | 8,000–25,000 |

Initial Investment vs. Long-Term Savings:

A 25,000high– efficiency shaker maysave 10,000/year in energy and maintenance costs compared to a $15,000 basic model.

ROI Calculation:

Example: A mining operation processing 500 t/h with a PU-screen shaker reduces screen replacements from 4x/year to 1x/year,saving $8,000 annually.

Cheap Imitations:

Low-cost shakers often use 201 stainless steel (prone to rust) instead of 304/316 SS.

Poor Screen Tensioning:

Inadequate tension leads to screen sagging, reducing separation efficiency by 30%+.

Overlooking Local Regulations:

Ensure compliance with API RP 13C (oil & gas) or ISO 9001 (general industry).

For Oil & Gas Drilling:

Choose Derrick FLC 500 Series for high-performance, corrosion-resistant screening.

For Budget-Conscious Buyers:

Consider TR’s ZS or TR’s PZS-583 for reliable mid-range performance.

The 2025 mud shale shaker market prioritizes efficiency, sustainability, and smart technology. By evaluating capacity, screen quality, brand reputation, and total cost of ownership, buyers can select a solution that maximizes productivity while minimizing long-term operational risks.

Pro Tip: Request a field trial before purchasing to test performance under real working conditions.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li