In oil extraction and processing, efficient separation of oil-water-solid mixtures is a key step. Drilling centrifuges leverage centrifugal force generated by high-speed rotation to achieve rapid separation of liquids and solid particles in drilling fluid, playing an irreplaceable role in conventional drilling, deep well and horizontal well operations across major domestic oilfields.

As oilfield exploration and development advance into deep and complex formations, drilling mud typically exhibits high solids content, sulfur and sand inclusion, and high viscosity. These properties often lead to problems like material clogging, equipment corrosion and wear, and incomplete separation during processing, which not only hinder drilling progress but also pose environmental risks due to non-compliant waste discharge. Drilling fluid centrifuges resolve these challenges through centrifugal sedimentation technology, maintaining drilling fluid performance, improving drilling efficiency, and are especially suited for harsh working conditions such as deep wells, complex geology, and high-temperature & high-pressure environments.

Decanter centrifuge (horizontal screw sedimentation centrifuge) is core solid-liquid separation equipment for oilfield drilling. Its working principle is as follows: the suspension enters the drum through the feed pipe and the liquid outlet of the screw conveyor. Under centrifugal force, solid particles are pushed to the inner wall of the drum, conveyed to the slag discharge port at the small end by the blades of the screw pusher, and the liquid phase overflows from the overflow port at the large end of the drum to realize continuous separation. It can efficiently treat solid particles with a particle size of 2-7um, enhancing drilling fluid separation efficiency.

To adapt to the harsh working environment of oilfields, the structural design of drilling centrifuges prioritizes key factors such as corrosion resistance, wear resistance, and sealing performance.

Corrosion-Resistant Materials:The drum and pusher are made of duplex stainless steel, which has excellent corrosion resistance, can resist the erosion of sulfur-containing mud, and extend the service life of the equipment.

Wear Protection:The inner wall of the drum and the diversion port of the pusher are protected by wear-resistant alloys, and the blades of the pusher are equipped with detachable wear-resistant liners. This improves the wear resistance of key components and reduces failures and maintenance costs caused by wear.

Dual Sealing Protection:The sealing part adopts "fluororubber + mechanical seal" dual protection, which effectively prevents mud leakage and avoids internal corrosion of the equipment. Fluororubber has excellent chemical corrosion resistance and sealing performance, and mechanical seal enhances the sealing effect to ensure no leakage during equipment operation.

Strong Intelligent Adaptability:Equipped with frequency conversion control system, it can realize the adjustment of working parameters and adapt to drilling fluid working conditions with different densities and viscosities.

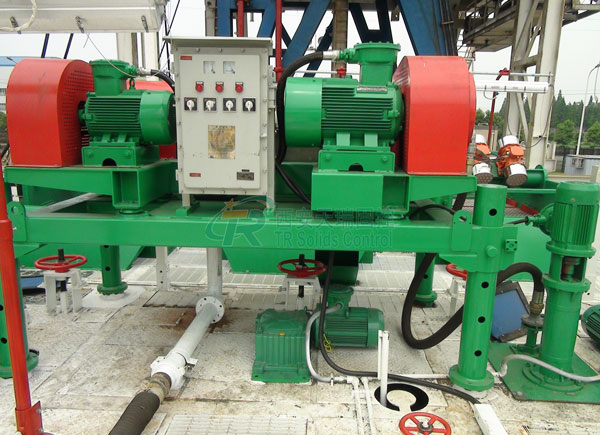

Drilling fluid centrifuges, as core solid-liquid separation equipment, are widely used in oil drilling, shale gas extraction, horizontal well construction and other fields. They can effectively control the density and viscosity of drilling fluid, ensuring drilling safety under complex working conditions. TR Solids Control, as an international comprehensive supplier, focuses on the design, manufacture and service of drilling fluid treatment equipment. Its drilling centrifuges have the advantages of high speed, large processing capacity and long service life.Customized solutions are available according to customer requirements, including different specifications such as horizontal screw type and high-speed frequency conversion type, as well as materials such as stainless steel and wear-resistant alloys.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li