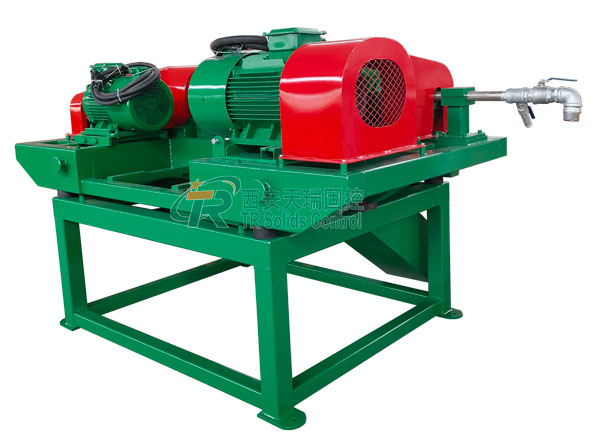

Solids control centrifuge is a key equipment in the solids control system of oil drilling mud, which is used to achieve efficient separation of solid and liquid phases in drilling fluid.

Drilling fluid centrifuges are core equipment in oil drilling solids control systems, primarily used to separate solids from drilling fluid, optimizing mud properties and reducing processing costs. So, how do centrifuges optimize efficiency and mitigate environmental risks in the oil drilling industry? Below, TR Solids Control analyzes centrifuge performance and efficiency optimization.

Drilling fluid centrifuges typically utilize a horizontal spiral settling structure (Decanter Centrifuge), consisting of a rotating drum, a spiral pusher, a drive system, and a control system. During operation, drilling fluid enters the high-speed rotating drum (which can rotate at speeds of 1500-4000 rpm) through a feed pipe. Centrifugal force propels solid particles toward the inner wall of the drum, forming a filter cake. The spiral pusher propels the filter cake to the discharge port at a slight differential speed (typically 1-50 rpm), while the liquid phase returns to the circulation system through the overflow port. Separation efficiency depends on the drum diameter, rotation speed, liquid pool depth, and differential speed control.

Core components are made of high-performance materials to enhance durability: the drum is mostly made of SAF2205 duplex stainless steel (with better corrosion and wear resistance than 304/316 stainless steel), the surface of the spiral pusher is inlaid with tungsten carbide wear-resistant alloy sheets, and the bearings are imported SKF/NSK products, ensuring long-term and stable operation of the equipment under harsh working conditions.

II. Performance analysis of centrifuge

According to separation factors and application requirements, drilling fluid centrifuges can be divided into low-speed centrifuges, medium-speed centrifuges and high-speed centrifuges.

Low-speed centrifuge (barite recovery type)

The speed is 1600-1800r/min, the separation factor is 500-700, and it is mainly used to recover high-density solid phase (such as barite) and reduce mud costs.

Medium-speed centrifuge (general type)

With a rotation speed of 1800-2200r/min and a separation factor of 800-1200, it takes into account both barite recovery and harmful solid phase removal, and is currently the most commonly used model by well crews.

High-speed centrifuge (fine separation type)

The speed is 2200-3500r/min, the separation factor is 1200-2100, and it focuses on removing low-density harmful solids (such as drill cuttings) of 2-5μm. It is often used in series with a low-speed centrifuge to form a dual-machine system.

Drive modes include:

Variable Frequency Drive (VFD): This system achieves stepless speed regulation through PLC programming and monitors parameters such as speed, torque, and bearing temperature in real time. It is highly intelligent and suitable for shale gas wells with complex operating conditions.

Hydraulic drive (FHD): It uses imported hydraulic pumps and motors, with large transmission torque, and can automatically adapt to changes in mud properties, especially suitable for oil-based mud processing.

Power frequency drive: fixed speed, low cost, suitable for conventional drilling fluid treatment.

III. Centrifuge efficiency optimization strategy

Through the above performance of the centrifuge, the centrifuge speed and differential speed are adjusted according to the viscosity and solid content of the drilling fluid, and the equipment parameter adjustment and waste management are optimized to achieve low energy consumption and good solid-liquid separation effect.

Precise matching of speed and processing capacity

Adjust the centrifuge speed according to the drilling fluid type (weighted/non-weighted). For example:

Weighted drilling fluid: High speed (3000-3250r/min) can separate 2μm barite and 3μm drill cuttings, recovering barite at an efficiency of 3-4 tons/hour, while reducing viscosity and reducing the need for drilling fluid dilution.

Non-weighted drilling fluid: Large-capacity centrifuges (30-50m³/h) can remove 3-4 tons of solids, significantly improving liquid recovery.

Principle: Stokes' law shows that the particle settling velocity is proportional to the square of the particle size, and speed optimization can maximize separation efficiency.

Process integration innovation

Series processing: shale shaker → desander → desilter → centrifuge, remove solids step by step according to particle size to prevent large particles from damaging the centrifuge.

Closed loop circulation: the underflow of the centrifuge returns to the circulation tank, and the overflow is discharged to the waste pool, reducing the waste of drilling fluid.

Hydrocyclone synergy: The cyclone underflow is sent to the centrifuge for secondary separation, increasing liquid recovery by 15% and reducing solid phase volume by 30%.

Equipment performance upgrade

Variable frequency speed regulation technology: Dynamically adjust the speed according to the viscosity of the drilling fluid to avoid excessive separation or energy waste.

Application of wear-resistant materials: The use of ceramic-coated drum extends the equipment life by 30% and reduces downtime for maintenance.

IV. Reduce environmental risks

Reduce pollutant generation at the source: Add a pre-treatment step before feeding the centrifuge, such as using a vibrating screen or desander to remove large solid particles. This will reduce the processing load of the centrifuge and reduce the subsequent processing volume of harmful solids (such as barite and chemical additives).

Optimize drilling fluid circulation and recovery: The clear fluid (liquid phase) efficiently separated by the centrifuge is reinjected into the drilling system for recycling, reducing the amount of fresh drilling fluid replenished. Only waste drilling fluid that cannot be recycled is handled in accordance with regulations, reducing waste fluid discharge.

Standardize solid waste treatment and disposal:

The dry solid phase separated by the centrifuge (the water content must be controlled below 15%) must be stored separately to avoid mixing with other pollutants.

When centrifuge separation efficiency is improved, the moisture content of the solid phase decreases, reducing subsequent solid waste transportation and disposal costs while also minimizing the risk of leachate contamination caused by excessively high solid phase moisture content. The increased volume of recycled drilling fluid not only reduces the cost of purchasing fresh drilling fluid but also directly reduces the environmental burden and treatment costs of waste fluid discharge. Drilling fluid centrifuges, through their efficient solid-liquid separation technology, play a key role in ensuring drilling safety, reducing costs, and ensuring environmental compliance.

As oil and gas development extends to deep and complex formations, high speed, intelligence and greenness have become the main development lines of the industry. Tianrui solids control equipment has been recognized by many industries in the market for its cost-effectiveness and technological breakthroughs, combined with specific working conditions (such as mud type, processing volume) and budget.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li