Derrick FLC503 Shale Shaker is specialized solids control equipment designed for drilling systems. With excellent screening performance and stable operation, it has become one of the widely used linear shale shakers in the oil drilling industry.

The Derrick FLC503 Shale Shaker adopts dual Super G motor drive design, achieving stable linear motion trajectory. It can operate continuously under high-intensity working conditions with 7.0 times the gravitational acceleration, ensuring rapid separation and high-efficiency screening of solid particles in drilling fluid.

High Screening Efficiency: Precisely separates cuttings particles and maintains stable drilling fluid performance

Large Processing Capacity: Meets mud treatment requirements of different drilling scales

Compact & Rational Structure: Small footprint, suitable for the limited space of drilling platforms

Low Power Consumption & Noise: Complies with energy-saving and consumption-reducing operation requirements

Durable Construction: The screen box is made of robust stainless steel, featuring excellent corrosion and wear resistance. It can adapt to the harsh working conditions of drilling environments and significantly extend the service life of the equipment.

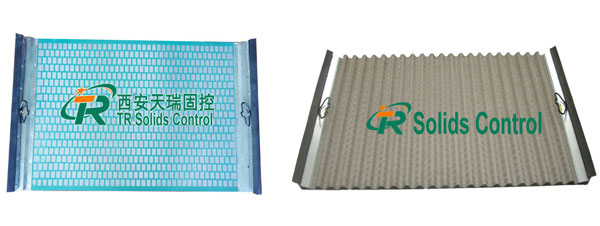

In terms of shaker screen adaptation and adjustment, the Derrick FLC503 Shale Shaker is compatible with flat shaker screens or pyramid wave shaker screens, and supports quick screen replacement to improve drilling operation efficiency. At the same time, during the drilling process, the screen angle can be flexibly adjusted within the range of -1° to +5° according to actual working conditions, further optimizing the screening effect and ensuring the accuracy of solids control.

TR Solids Control manufactures special shaker screens compatible with the Derrick series shale shakers, including flat screens and wave screens suitable for the FLC500 and FLC2000 series. All shaker screens are produced in strict accordance with the internationally recognized API RP13C screening standard, meeting the solids control requirements of the oil drilling industry.

To meet the drilling system configuration needs of different customers, TR Solids Control provides personalized product selection advice, technical support, and after-sales maintenance services. From equipment supply to parts matching, from installation guidance to troubleshooting, we comprehensively support the efficient implementation of drilling operations. For more product parameters, price information, or customization needs, please feel free to contact us: +86-13186019379

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li