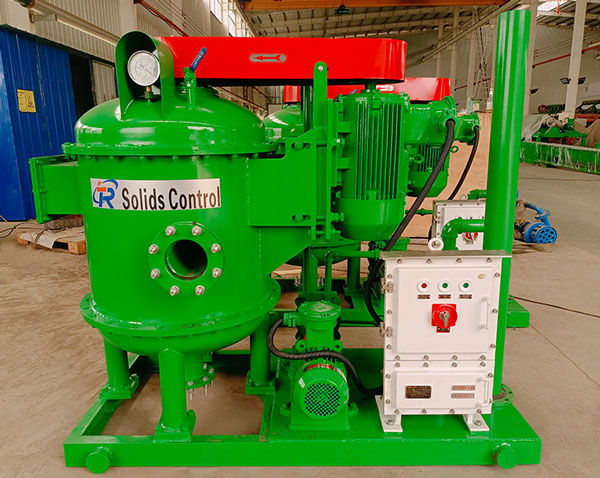

Recently, TR Solids Control successfully delivered several sets of TRZCQ series vacuum degassers, which have been shipped to Saudi Arabia for use in local drilling solids control systems, undertaking the key gas-liquid separation task during drilling operations. The vacuum degasser can effectively remove petroleum liquid gas from the mud returned from the wellhead and various gases entrained in the gas-cut mud, providing equipment support for the safe and efficient advancement of local drilling operations.

As supporting equipment for drilling solids control system, the performance of the vacuum degasser directly affects the stability of mud performance and the safety of drilling construction. This export also marks that TR Solids Control's products have gained further recognition in the international market, expanding TR Solids Control's overseas layout in oilfield equipment.

TR Solids Control TRZCQ series vacuum degassers have many characteristics relying on their unique structural design and excellent service performance:

1. The vacuum pump is used for suction to make the mud enter the vacuum tank and the gas be pumped out of the vacuum tank, and the vacuum pump plays two different roles.

2. The water ring vacuum pump is always in an isothermal state during operation, suitable for suction of flammable and explosive gases, safe and reliable.

3. The mud is shot at the four walls at high speed through the rotor window, the bubbles are completely broken, and the degassing effect is good.

4. The main motor is offset to reduce the center of gravity of the whole machine.

5. Belt drive is adopted to avoid the complex design of the reduction mechanism.

6. The application of the gas-water separator avoids the simultaneous discharge of water and gas, ensures the smoothness of the exhaust pipe, and can cyclically supply water to the vacuum pump to save water.

TR Solids Control vacuum degasser can quickly remove gases from gas-cut mud, restore mud specific gravity, and stabilize mud performance. It features compact design and small floor space. Compared with similar foreign products under the same processing capacity, it has lower power, and the unique structural design directly discharges the treated mud.

The vacuum degasser ensures the appropriate density of mud required for drilling, effectively prevents the occurrence of blowout, thereby ensuring the safety of mud drilling. In addition, it can effectively ensure the normal operation of subsequent solids control equipment and mud pumps, reduce equipment failures, improve drilling efficiency, and provide greater support for the quality and efficiency improvement of customers' projects.

To adapt to different processing capacities, TR Solids Control TRZCQ series vacuum degassers are divided into TRZCQ240, TRZCQ270, TRZCQ300 and TRZCQ360, which can meet the processing needs of different working conditions and be used with various mud purification systems. TR Solids Control will continue to provide high-quality solids control equipment for the global drilling industry, helping overseas customers achieve efficient, safe and green drilling.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li