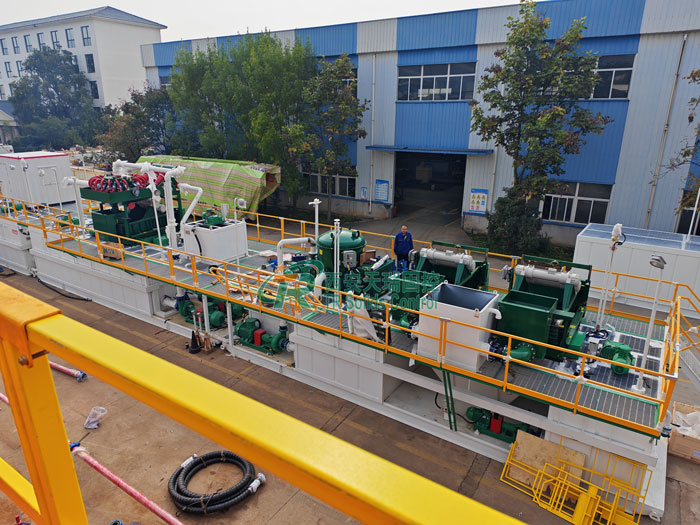

The 50 solids control system used in oilfields (usually referring to the ZJ50 drilling rig solids control system) is the core equipment for drilling fluid purification, mainly used for separating drill cuttings, recovering barite, and removing harmful gases. Tianrui solids control is divided into multi-stage purification units according to processing needs to achieve effective drilling fluid recycling.

Shale Shaker

As the primary processing unit, is equipped with two high-frequency linear shale shakers to separate coarse drill cuttings with a particle size greater than 74 micrometers through multiple layers of screens. Its processing capacity directly affects the load on subsequent equipment, and the screen mesh size can be adjusted according to the characteristics of the drilling fluid (e.g., API 200 mesh for weighting mud).

Vacuum degasser

Vacuum degasser used to remove free gas from drilling fluid and prevent well control risks caused by gas intrusion. Tianrui's client chose the Vacu-FLO 1200, which uses a vacuum pump to create negative pressure (0.030-0.050 MPa) inside the tank, causing air bubbles to burst and escape. This equipment is typically installed after a shale shaker to directly process the pre-screened drilling mud.

Desander And Desilter

The desander separates medium-sized particles (45-74 microns) using a hydrocyclone, while the deslimer handles fine particles (15-44 microns). For example, TR Solids Control's ZJ50 system is equipped with a Hyperpool desander and deslimer, with a processing capacity of up to 240 m³/h. Some systems also integrate a Mud Cleaner, combining the desander/desliter with a fine-mesh vibrating screen for further barite recovery.

Decanter Centrifuge

As a fine processing device, a medium-speed or high-speed centrifuge can be selected based on efficiency. The medium-speed centrifuge is used to recover barite (separating 5-7 micron particles), while the high-speed centrifuge processes non-weighted slurry (separating 2-5 micron particles).

Mud Tank

As the system carrier, TR Solids Control's 50 Solids Control System consists of four modular tanks with a total effective volume of 246 cubic meters. The tanks are divided into sedimentation tanks, degassing tanks, desanding/desludge tanks, and centrifuge tanks, connected by pipelines and aqueducts to form a five-stage purification process (screening → degassing → desanding → desludge → centrifugation). For example, Tank 1 has a sedimentation tank (20 cubic meters) and a true desanding tank (11 cubic meters), while Tank 2 integrates a desanding/desludge device and a medium-speed centrifuge.

Sand Pump & Centrifuge Pump

Desander, Desilter, and centrifuges require matching sand pumps to provide high-pressure power. For example, Tianrui's sand separator pump equipped with a 55kW explosion-proof motor can achieve a flow rate of 240m³/h and a head of 30 meters; the centrifuge supply pump adjusts its parameters according to the centrifuge model (e.g., driven by a 37kW motor).

Agitator & Mixing System

Each compartment is equipped with a 15kW horizontal agitator to prevent solid precipitation; the mixing tank is equipped with a shear pump and a jet funnel for rapid addition of bentonite, chemicals, or barite. Some systems also integrate intelligent monitoring modules, providing real-time parameter feedback through pressure sensors and mechanically graduated level gauges.

Mud tank installation

Hoist the mud tank according to the design requirements, ensuring that the tank is level and tightly connected to prevent drilling fluid leakage.

Install level gauges, agitators, and other accessories to ensure accurate level monitoring and stable agitator operation.

Shale shaker installation

Hoist the shale shaker above the mud tank and adjust the screen angle (usually 10°-15°) to ensure uniform distribution of drilling fluid.

Connect the feed pipe to the shale shaker and the mud tank, ensuring the pipe diameter matches to reduce fluid resistance.

Desander and Desilter installation

Hoist the desander and desliter to the designated position, connect the inlet and outlet pipes, and ensure that the hydrocyclone is in the correct direction.

Adjust the inlet pressure (usually 0.25-0.35 MPa) to ensure separation effect.

Centrifuge installation

The centrifuge is hoisted to the side of the mud tank and fixed on a special base, ensuring that the coaxiality error between the drum and the screw conveyor is less than 0.1mm.

Connect the feed pipe and discharge pipe between the centrifuge and the mud tank, and install protective covers and safety valves.

Manifold and electrical control system installation

Lay manifolds to connect the inlet, outlet, and slag discharge pipelines between various equipment, ensuring good sealing.

Install the electrical control cabinet, connect the equipment motors, sensors and actuators, and perform electrical wiring debugging.

Stand-alone debugging

Start the shale shaker, desander, desilter , centrifuge and other equipment in sequence, and check the operating status (such as vibration frequency, speed, noise, etc.).

Verify the accuracy of readings from sensors such as level gauges and flow meters, and adjust control parameters to the design range.

System linkage debugging

The drilling fluid circulation process is simulated, with the drilling fluid returning from the wellhead passing through equipment such as a shale shaker, desander, desilter, and centrifuge in sequence.

Monitor parameters such as solid content, viscosity, and density of the drilling fluid at the outlet of each device to ensure that they meet drilling process requirements.

TR Solids Control's ZJ50 solids control system employs a multi-stage purification process: wellhead return mud → vibrating screen separates coarse particles → sand chamber temporarily stores mud, followed by vacuum degassing → desander separates medium particles → desilter treats fine particles, medium-speed centrifuge recovers barite → high-speed centrifuge removes colloidal particles → purified mud is returned to the circulation tank, etc. This achieves drilling fluid recycling and environmental compliance, while reducing costs and improving drilling safety and high-quality efficiency.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li