The shaker screen mesh is component that directly contacts drilling fluid and solid particles, resulting in high failure rate that directly affects screening efficiency, throughput, and drilling fluid recovery. Based on the actual operating conditions of oil drilling solids control systems (such as high temperature, high solids content, corrosive mud, and high-frequency vibration), the following details the fault symptoms, causes, and solutions/prevention measures.

Q1: Frequent clogging of the screen during use leads to a decrease in drilling fluid treatment capacity. What are the main reasons for this, and how can it be resolved?

A1:There are four main reasons for screen clogging: First, the particle size does not match the screen mesh size, resulting in the accumulation of large particles; second, the drilling fluid has high viscosity, causing fine particles to adhere to the screen holes; third, the vibration parameters are unreasonable, resulting in insufficient rapping force; and fourth, the screen is not cleaned in time, leaving residual particles that clog the holes.

Solution:① Replace the matching screen according to the particle distribution; ② Adjust the drilling fluid formula within the allowable range of the process to reduce the viscosity; ③ Adjust the eccentric block angle or motor frequency to optimize vibration parameters and enhance the rapping effect; ④ Establish a regular cleaning system and wash the shaker screen surface with high-pressure clean water or special cleaning agent.

Q2:What factors might cause localized damage or tearing of the shaker screen shortly after use? How can this be prevented and addressed?

A2:Factors contributing to localized damage to shaker screen: ① Poor screen quality, insufficient material strength, or defective weaving; ② Improper installation, resulting in loose or misaligned screens causing uneven stress in certain areas; ③ Concentrated impact from feeding material, with drilling fluid directly hitting a localized area of the screen; ④ Foreign objects such as metal shavings inside the screen frame scratching the screen.

Treatment measures:① Select high-quality shaker screens from reputable manufacturers and verify their quality upon arrival; ② Install according to specifications, clean debris from the screen frame, and ensure the screen is flat and taut; ③ Add a buffer plate to the feed inlet to ensure even distribution of drilling fluid; ④ Repair minor damage with special adhesive, and immediately stop the machine and replace the screen for large-area damage.

Q3:When the shale shaker is running, the shaker screen runs off-center, with one side of the screen surface tightly against the screen frame and the other side tilting up. How can this be resolved?

A3:Shaker Screen misalignment is caused by force imbalance, which has three reasons: ① Improper adjustment of the tensioning mechanism, resulting in uneven tension on both sides; ② Asymmetrical angle of the eccentric block of the vibration shaft, resulting in uneven vibration amplitude of the screen frame; ③ Feed deviation, with one side being subjected to long-term impact.

Solution steps:① Stop the machine and adjust the tensioning mechanism to ensure that the tension on both sides is consistent. After adjustment, push the screen to confirm that it is stable. ② Check and calibrate the angle of the eccentric blocks on both sides until they are consistent. ③ Adjust the feed guide device so that the drilling fluid falls to the center of the screen surface.

Q4:After a period of use, the screening efficiency of the screen decreases significantly, but no obvious blockage or damage is found. How can the screening efficiency be improved?

A4:The screening efficiency decreased without obvious damage or blockage. The reasons include: ① screen aging, reduced wire elasticity, and poor vibration transmission; ② vibration parameters not matching the current working conditions; ③ unreasonable screen inclination angle and abnormal drilling fluid residence time; ④ large gap between the screen and the screen frame, resulting in a "short circuit".

Improvement measures:① Replace the shaker screen if the wire mesh is loose or deformed; ② Readjust the vibration parameters according to the drilling fluid viscosity and solid content; ③ Adjust the support feet according to the instruction manual and set the inclination angle to 15°-25°; ④ Replace the sealing strip or adjust the shaker screen to prevent "short circuit".

Q5:In shale shaker using multiple shaker screens in combination, some screens fail prematurely while others continue to function normally. How can this "local failure" problem be solved?

A5:The core issue of partial failure of multiple sets of screens is uneven load distribution. The reasons are: ① Improper matching of screen mesh size, with the upstream stage failing to trap large particles and overloading the downstream stage; ② Poor connection of screen surfaces, with steps or gaps causing concentrated stress on the accumulated liquid; ③ Inconsistent tension of each set of screens, with particles accumulating in the looser ones.

Solution:① Match screens according to the principle of "from coarse to fine" to reduce the load on subsequent stages; ② Repair the connecting parts and replace the seals to ensure the screen surface is flat; ③ Tighten all sets of screens uniformly, establish replacement records, and shorten the inspection cycle of vulnerable parts.

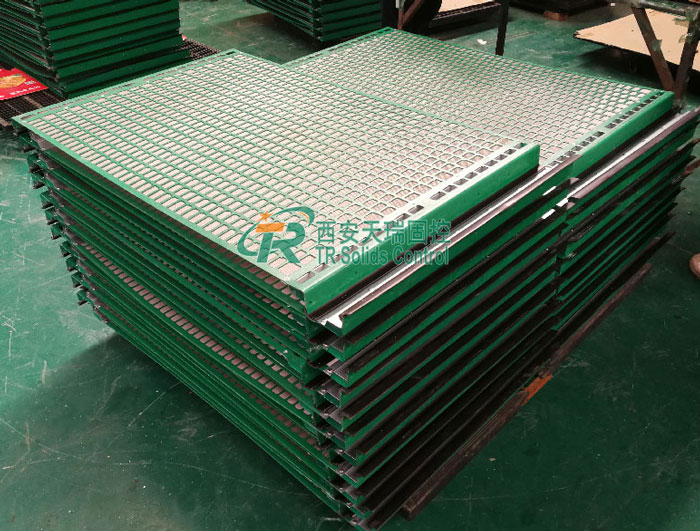

Shaker Screen is key component of shale shakers, directly affecting the screening efficiency of oil equipment. Frequent use in drilling shaker screens also makes it wear part, requiring regular inspection and the availability of spare screens for timely replacement. TR Solids Control's shaker screens can replace Derriok and Swaco shaker screens, possess API certification, and have been sold to many countries internationally. Customer feedback indicates they offer excellent value for money.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li