Recently, TR Solids Control’s Drilling Mud Mixing System, custom-built for German client, is set to be shipped and delivered. This achievement not only expands the company’s footprint in the German drilling market but also showcases its technical prowess and manufacturing capabilities in solids control and mud mixing systems.

The Drilling Mud Mixing System is critical in drilling engineering, mainly composed of mixing device, mud tanks, and other key components. In solids control system, mud tank is also known as mixing tank or storage tank. Widely used in oil drilling, horizontal directional drilling (HDD), and coalbed methane exploration, and is an essential piece of equipment for storing drilling mud in mud treatment equipment and mud mixing and circulation systems.

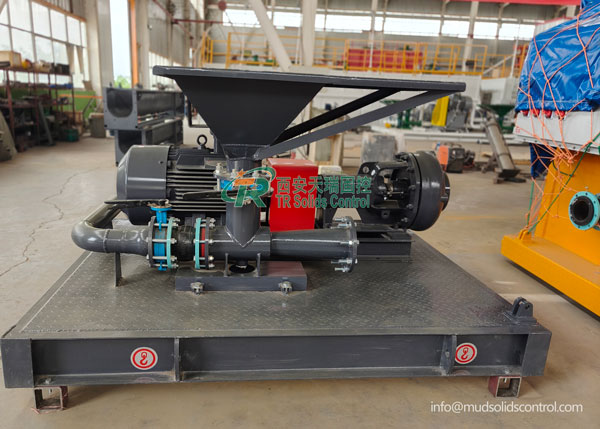

The Drilling Mud Mixing System delivered to the German customer comprises 4 sets of mud tanks. Each mud tank is equipped with agitators and mud mixing equipment, and also integrates basic equipment such as electrical controls, with effective volume of 50 cubic meters. The complete drilling mud mixing system encompasses more comprehensive range of equipment, including mud mixing tanks, jet mixing devices, centrifugal sand pumps, desilters, shale shakers, mud agitators, and mud guns.

Integrated into complete and efficient drilling fluid mixing system, its core function is to precisely mix drilling fluid, ensuring key indicators such as density and viscosity meet the standards and requirements for drilling operations.

In drilling operations, whether for oil drilling or horizontal directional drilling (HDD), the drilling mud or fluid required for drilling needs to be mixed before being reinjected, thus forming mud circulation system. Jet mixing devices play crucial role in this process. Boasting advantages such as high efficiency, energy savings, easy maintenance, and user-friendly operation, quickly mixing mud from top to bottom and reducing the mixing time. Suitable for industrial applications requiring high-quality mixing, especially in the mixing of materials in drilling fluid systems. This significantly improves work efficiency, reduces costs, enhances drilling fluid performance, and provides strong support for the smooth progress of drilling operations.

TR Solid Control, as a professional manufacturer in the drilling solids control equipment sector, is committed to providing customers with high-quality solid control systems and mud mixing system solutions. Beyond the mud mixing system delivered this time, TR Solid Control also possesses the capability to manufacture complete range of solid control equipment, including key equipment such as mud shale shakers, desanders and desilters, drilling fluid centrifuges, and vacuum degassers. TR can customize mud mixing systems to suit various drilling scenarios based on different working conditions.These equipment are widely utilized in drilling sectors including oil, natural gas, geothermal energy, and shale gas. Backed by reliable quality and professional performance, TR provides comprehensive technical support and services to global clients, earning high recognition and trust across the industry.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li