In solids control system of drilling engineering, the drilling desilter adopts precision separation technology to further separate muddy particles from drilling fluid, thereby improving mud cleanliness. It is mainly designed for separating 15–44 microns solid particles, undertaking the in-depth purification task after shale shakers and desanders in the solids control process.

The drilling fluid desilter realizes efficient solid-liquid separation of drilling fluid based on the combined effects of particle sedimentation and centrifugal force. When drilling fluid enters the desilter spirally along the inner wall of the hydrocyclone, the high-speed rotating centrifugal drum generates strong centrifugal force. Due to higher density than liquid, solid particles in drilling fluid are quickly thrown to the device wall under centrifugal force, while clean drilling fluid flows out from the central outlet. In some working conditions, the fluid is subjected to secondary separation via fine-mesh shale shaker, and the clear liquid rises spirally for recycling. Meanwhile, gravity helps settle some heavier solid particles at the bottom of the drilling desilter.

The value of this equipment lies in purifying mud performance, protecting downstream precision equipment such as centrifuges, improving mud recovery rate, reducing construction costs and environmental pressure.

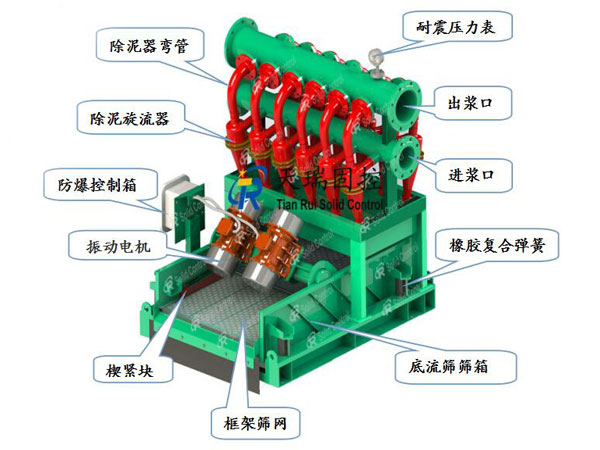

Hydrocyclone Design:Crafted from 100% polyurethane material, it boasts excellent wear resistance and significantly prolonged service life. The clamp-type connection structure simplifies maintenance procedures, enabling quick and flexible assembly for users. Depending on processing capacity requirements, it can be flexibly configured with 8–20 units of 4" or 5" hydrocyclones, suitable for different engineering scenarios.

Bottom Shale Shaker:Integrated with small-sized dual-screen mud shale shaker, it features large processing capacity and low noise. The screen adopts soft hook edge design for longer service life. Some models are equipped with shock absorbers, which greatly reduce operational vibration and noise pollution.

Structural & Performance Advantages:The compact overall design occupies small space, ideal for construction environments with limited site area. The symmetrical liquid inlet mechanism ensures uniform hydrocyclone distribution and strong stability. The underflow port of the hydrocyclone adopts pressurized umbrella-shaped "wet bottom" sand discharge design, accelerating particle discharge and reducing the probability of blockage.

The desilter products of TR Solids Control have obtained international certifications such as API, CE and ISO14001, meeting global export standards and complying with engineering specifications of different countries and regions. The material and structural design of the hydrocyclone balance durability and maintenance convenience. The combination of clamp-type connection and polyurethane material synchronously improves equipment service life and operation & maintenance efficiency. In addition, TR Solids Control's desilter also adopts shock absorption design. Through the combination of a constant pressure pump and shock absorbers, it achieves low-noise and stable operation. Even under harsh construction conditions, it can maintain stable working performance, providing reliable guarantee for the efficient progress of drilling engineering.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li