In the realm of oil and gas drilling, the shaker screens utilized in shale shakers holds critical importance in the solid control process.Shale Shaker Screens perform a precise function in filtering drilling fluids; they not only extract larger solid cuttings from drilling fluid (mud) but also separate solids from liquids, thus ensuring drilling efficiency. However, amidst the myriad choices available, selecting the high-quality shale shaker screens can be an overwhelming task.

Understanding about the Shale Shaker Screen and its Role

Before delving into the nuances of screen selection,comprehending the primary role of a shale shaker screen is vital. The shale shaker is a core piece of equipment in solids control system.Its primary function involves sieving drilling fluids and extracting solid particles while enabling the purified fluid to circulate seamlessly, thereby optimizing the drilling process.

Types of Shale Shaker Screens

Shaker screens for shale shaker comes in varied types, each designed for a specific function. Common types include:

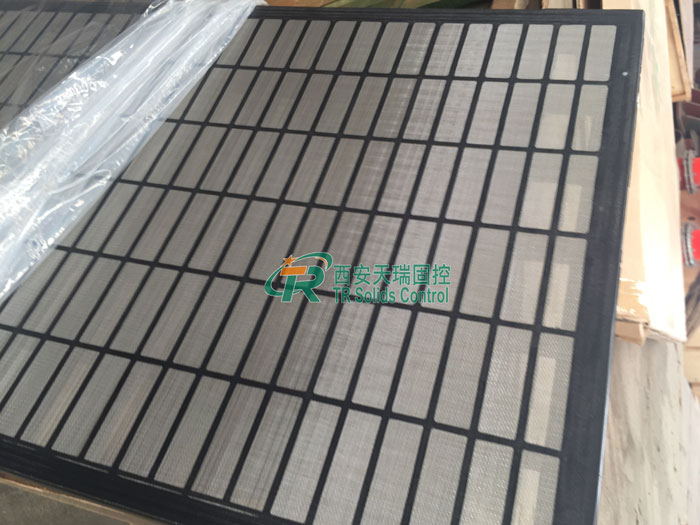

Hard hook edge screen: Known for their hassle-free installation and removal, these meshes are a preferred choice across diverse drilling operations.

Composite Frame Shale Shaker Screens: These screens combine a steel frame with a composite material. They offer increased longevity, improved resistance to corrosion, and often have higher conductance.

Polyurethane screens: Good elasticity, impact resistance, wear resistance and corrosion resistance, and is suitable for screening high-impact and fine-particle materials. There is no risk of fiber shedding and the probability of screen blockage is low, thus extending the service life.

Mesh Rating for Shale Shaker Screens

The mesh rating system is crucial in the oil and gas industry, particularly in shale shaker screens used for solids control.The size of the required shaker screen is based on the size of the particles that can pass through a screen.

Confirm the mesh size according to the screening requirements (1 mesh = number of sieve openings per inch). Check whether the actual mesh size matches the label. High-quality sieves have a mesh size deviation of ≤±2% and a mesh uniformity deviation of ≤±5%. This can be achieved through "standard sample comparison" (stack a sample with a known precise mesh size with the sieve to be selected and observe the mesh alignment under transmitted light) or "particle test screening" (test with standard particles of known particle size; the ratio of missed/passed screening must meet the requirements, such as a 200-mesh sieve for petroleum solids control, which needs to intercept solid particles ≥75μm with a missed screening rate of ≤3%).

TR Solids Controls offers shale shaker screens ranging from API20 to API400, with API standards conforming to those set by the American Petroleum Institute (API). These screens are categorized based on mesh size and flow carrying capacity.

Understand mesh size and configuration

Mesh size directly affects screening efficiency (no gaps, no clogging) and the accuracy of material classification. Mesh size refers to the number of holes per inch of length, which directly affects the mesh's filtration capacity. Finer mesh sizes effectively filter smaller particles, while larger mesh sizes allow larger particles to pass through.

Mesh count and mesh size matching:

No risk of mesh deformation/clogging: High-quality screens are tightly woven with no burrs or collapses at the mesh edges, and the woven wire diameter is uniform (wire diameter deviation ≤ ±0.03mm); inferior screens are prone to uneven wire diameter and mesh stretching deformation, which can easily cause clogging or leakage during screening, leading to material grading failure.

Enhance your drilling operations with precision and efficiency. Inquire about TR Solids Control's premium shale shaker screen series. We offer a comprehensive screen selection guide to ensure you obtain an optimized solids control system for your specific drilling needs. Contact us to find the perfect solution that combines durability, high performance, and cost-effectiveness for seamless drilling operations.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li