Shale shaker are essential equipment in industrial production, and screen material and specifications directly impact screening efficiency and service life. However, different industries have vastly different requirements for shaker screen mesh, making selection difficult for many. So, what kind of shaker screen is suitable for each industry? How can you choose the right material and specifications based on your needs? Below, TR Solids Control will provide an in-depth analysis of the application differences of shaker screen mesh across different industries and provide you with professional advice.

The material of the screen needs to match the material characteristics, screening accuracy, use environment and cost requirements, and the specifications and models need to correspond to the material particle size and screening efficiency requirements.

1. Screen material and selection

The material is the key to determining the life of the screen and the screening effect, and needs to be selected based on factors such as the corrosiveness, hardness, and temperature of the material.

| Material type | Core features | Applicable scen |

| Stainless steel(304/316L) | Corrosion-resistant, rust-proof, sanitary | Food, medicine, chemicals |

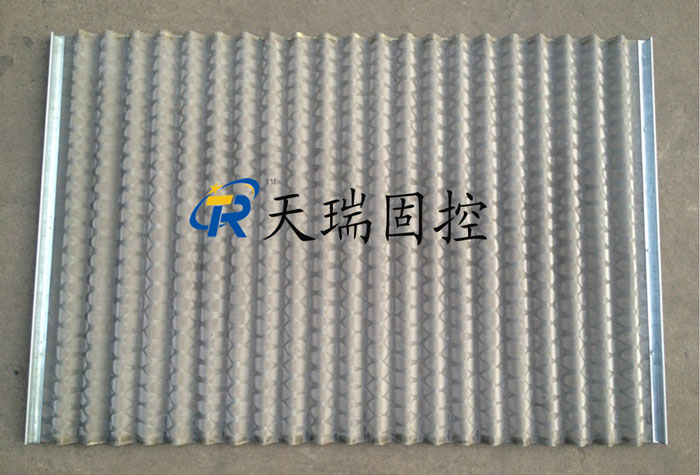

| Manganese steel(65Mn) | High hardness, wear resistance, strong toughness | Mines, sand and gravel |

| carbon steel(Q235) | Low cost, easy processing, average strength | Non-corrosive, low-wear materials |

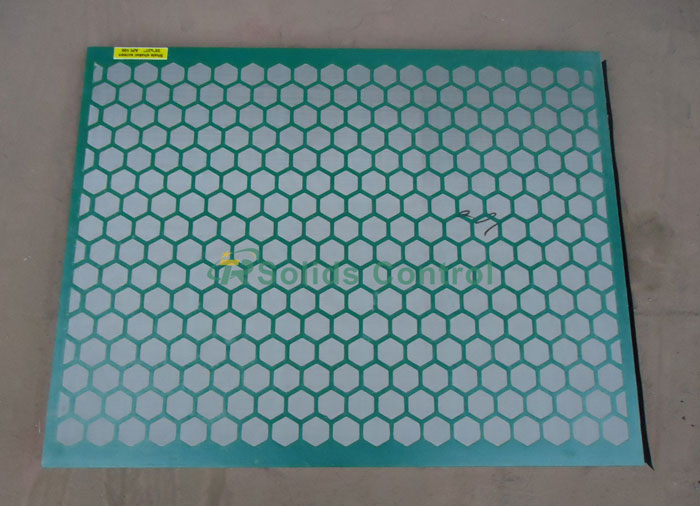

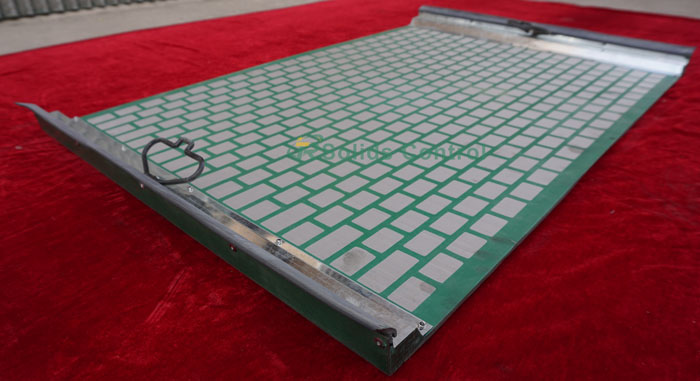

| Polyurethane(PU) | Good elasticity, shock-resistant, low noise | Wet screening (such as mud dewatering), brittle materials |

2. Key Specifications of Screen

Screen specifications are primarily expressed by their mesh number, which indicates the number of openings per square inch. High-mesh screens are suitable for screening powders or fine particles, while low-mesh screens are better suited for screening coarse particles or bulky materials. Specifications directly determine the sieving particle size, so pay attention to the following three key factors:

Mesh size: the size of the sieve holes, usually in mm or mesh (1 mesh ≈ 0.15mm), which needs to match the target screening particle size (e.g., to screen 5mm sand and gravel, a 5mm mesh should be selected).

Wire diameter: refers to the diameter of the screen metal wire. The thicker the wire diameter, the stronger the screen's bearing capacity, but the opening rate will be reduced; conversely, the screening efficiency is high but the life is short.

Opening rate: the ratio of the screen hole area to the total area of the screen. The higher the opening rate, the faster the material passes through and the higher the screening efficiency.

The specifications of screens are differentiated by mesh size, thickness and temperature resistance. The following are recommended screen specifications for different industries:

-Fine screen (10-50 mesh): suitable for fine screening, commonly used in food and chemical industries.

-Medium screen (50-200 mesh): generally used for medium particle screening in the mining and metallurgical industries.

-Coarse screen (200 mesh and above): widely used in screening of mines or construction materials.

Different materials of screens have differences in wear resistance, corrosion resistance, screening rate and cost.

| Performance indicators | Manganese steel screen | stainless steel screen | Polyurethane screen | Rubber screen |

| Wear resistance | Surface hardening, long life | Wear resistance, not as good as high manganese steel | Good elasticity and impact resistance | Weak wear resistance |

| Corrosion resistance | Anti-rust treatment | 316L has excellent corrosion resistance | Chemical resistance | Acid and alkali resistant |

| Screening rate | High opening rate | Woven structure with good screening | Rib width affects screen penetration | Elasticity affects screening |

| cost | high price | medium price | High price, but long life | low price |

3. Industry demand and screen selection

Material selection for shaker screens in different industries

Chemical industry: corrosion resistance is key

The chemical industry often handles acidic, alkaline, and corrosive substances, requiring screen materials with excellent corrosion resistance. Stainless steel (such as 304 or 316 stainless steel) is recommended for its corrosion resistance, high screening accuracy, and long life.

Mining industry: wear resistance cannot be ignored

The mining industry screens large quantities of ore or gravel particles, making wear resistance of the screen a top priority. High-manganese steel screens are a good choice. This material, hardened to withstand impact and wear, is suitable for heavy-duty screening operations.

Food industry: Hygiene level determines material

The food industry has strict hygiene requirements, so the screen material should meet food-grade standards. 304 stainless steel is a common choice, as it is not only safe and non-toxic, but also easy to clean and prevents material contamination.

Pharmaceutical industry: high precision and hygiene are equally important

The pharmaceutical industry requires extremely high precision in raw material screening, and the screens must also be non-toxic and sterile. 316L stainless steel screens are a popular choice in the pharmaceutical industry due to their higher corrosion resistance and hygienic properties.

The following is a reference table based on the different materials, specifications and models of the screen and the needs of different industries.

| industry | Recommended materials | Typical specifications | core needs |

| Mining/Metallurgy | Polyurethane, high manganese steel, stainless steel | Aperture 5-100mm, wire diameter 3-12mm | Strong wear resistance and impact resistance |

| Chemical/Electronics | 304/316Stainless steel, polytetrafluoroethylene | 200 mesh-800 mesh, resistant to strong acid and alkali | Extremely corrosion resistant, high purity requirements |

| Construction/Coal | Carbon steel (galvanized), polyurethane | Aperture 5mm-50mm, plate thickness 1-8mm | Low cost, high strength |

| Food/Medicine | 316L stainless steel, nylon | 120-400 mesh, dense grain structure | High hygiene standards and corrosion resistance |

| plastic/feed | Nylon, stainless steel | 80 mesh-200 mesh, square hole/long hole | Good toughness, no metal pollution |

How to choose the right screen model for you?

It is crucial to choose the appropriate screen model according to different material properties and production requirements.

The material and specifications of the vibrating screen mesh directly impact the efficiency and effectiveness of the production process. If you're struggling to choose the right mesh, we're here to provide you with professional advice. For specific inquiries, please call 029-86332919!

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li