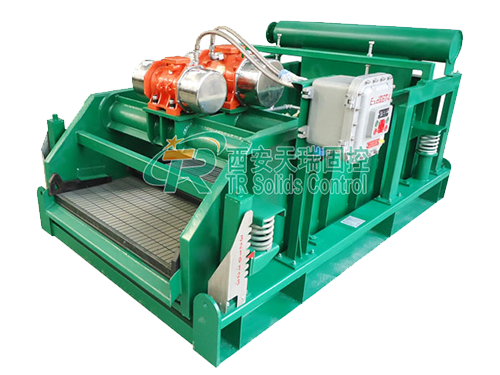

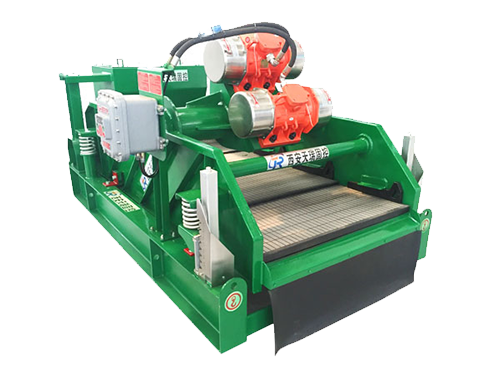

As a supplier of mud shale shakers, TR Solid Control specializes in drilling mud desanding and mining mud dewatering equipment. Utilizing high-quality steel and wear-resistant screens, the equipment features adjustable vibration frequency, high separation accuracy, and adaptability to various working conditions. TR provides free technical solutions and after-sales maintenance to solve mud treatment problems.

When selecting the type of drilling mud shale shaker, it is necessary to comprehensively consider the specific needs of the drilling project, mud characteristics, processing capacity requirements, and equipment performance characteristics to customize a suitable and durable shale shaker and solve problems that may be encountered during long-term use.

Features: Linear motion is generated by a pair of eccentric shafts rotating in opposite directions, and the trajectory of the screen box is a straight line.

Advantages: The movement of drill cuttings on the screen surface is regular, and the cuttings are discharged smoothly; the acceleration and force on the screen are more uniform and the direction is kept constant, allowing the use of ultra-fine screens with a longer service life; the drilling fluid processing capacity is 20% to 30% greater than that of a circular screen.

Applicable scenarios: Suitable for drilling projects that require efficient processing of large quantities of drilling fluid and have high requirements for screening efficiency.

Translational elliptical motion shale shaker:

Features: The vibration intensity is relatively moderate, the screen box moves in translational motion along with the center of mass, and the trajectories of each point on the screen surface are approximately the same circle.

Advantages: It can effectively remove solids from drilling fluid and eliminate larger particles, while reducing screen consumption.

Applicable scenarios: Suitable for drilling projects that require high screen life and a balance between throughput and screening efficiency.

Longitudinal tension screen:

Features: The screen is taut along the longitudinal direction.

Advantages: The tensioning method is simple, easy to operate and maintain.

Applicable scenarios: Suitable for drilling projects where the screen tension requirement is not high and the screen needs to be replaced quickly.

Lateral tension screen:

Features: The screen is taut in the transverse direction.

Advantages: Better tension, flatter screen, which helps improve screening efficiency.

Applicable scenarios: Suitable for drilling projects that require high screening efficiency and long-term continuous operation.

Multi-layer shale shakers can be customized if required. Single-layer screens are suitable for drilling operations with small throughput and low screening accuracy requirements. Double-layer shale shakers have two screens: the upper screen has a larger aperture, and the lower screen has a smaller aperture, enabling multi-stage screening, improving screening efficiency, and reducing screen clogging and wear. Double-layer mud shale shakers are suitable for drilling projects with large throughput and high screening accuracy requirements.

TR Solids Control's high-frequency mud shale shakers utilize high-frequency vibration and shaker screens of varying mesh sizes to effectively separate solid particles from drilling mud, maintaining mud performance and improving drilling efficiency. The screens are made of wear-resistant and corrosion-resistant materials, and different specifications and materials can be customized to meet diverse drilling needs.

TR Solids Control, as a custom manufacturer of mud shale shakers and drilling mud treatment equipment, possesses strong technical capabilities, product advantages, and customized service capabilities, making it a reliable partner in the drilling engineering field. TR Solids Control's products are widely used in the petroleum, oil and gas drilling and exploration industry, trenchless engineering, geotechnical engineering, mining, metallurgy, coal, hydropower, and other industries.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li