Mud Recycling System works in concert with multiple solids control devices. The core equipment can be divided into three categories according to the purification process: pretreatment, fine treatment, and auxiliary support, forming gradient separation system from coarse to fine, so as to realize the purification and recycling of drilling fluid.

Mud Recycling Systems are essential components in oil and gas drilling and trenchless construction projects. They remove solid impurities such as cuttings and sand from drilling fluid (mud) through a series of solids control devices, enabling mud recycling. This not only reduces mud consumption and environmental pollution but also improves drilling efficiency and construction safety. The following section details the main solids control equipment included in mud recycling system and illustrates its application value using case study from TR mud systems.

The solids control equipment in mud recycling system is configured according to separation precision from low to high, forming "multi-stage purification" mode to ensure that solid particles in the mud are separated step by step, ultimately meeting the mud performance requirements of drilling operations. The main equipment includes shale shakers, desanders, desilters, and centrifuges. Some systems are also equipped with auxiliary equipment such as vacuum degassers, sand pumps, and agitators.

Shale Shaker: "first line of defense" in solids control systems

The shale shaker is first purification device in solids control system for mud, used to separate larger rock fragments and sand particles (typically larger than 75μm) from mud. Its working principle involves motor driving the screen box to vibrate, using the sieving action of the screen mesh to trap and discharge solid particles larger than the mesh openings, while the mud that meets the requirements enters subsequent purification stages.

The performance of shale shaker depends on the screen material, vibration frequency, and amplitude. High-quality shale shaker can effectively reduce the initial solids content of the drilling mud, thus reducing the load on subsequent equipment. In complex drilling conditions, such as shale gas drilling, shale shaker also needs to be anti-clogging and wear-resistant to meet the requirements of mud treatment with high sand content.

Desander:Key equipment for intermediate purification

Even after being processed by shale shaker, the drilling mud still contains significant amount of fine particles (between 20-75 μm in diameter). If these particles are not removed in time, they will exacerbate wear on drilling equipment and affect the performance of the drilling mud. Desander is purification device specifically designed for these particles. Its components consist of hydrocyclone and matching shale shaker (usually fine screen).

The working principle of desander is based on centrifugal sedimentation: slurry is fed into hydrocyclone under pressure, forming high-speed rotating vortex. Solid particles move towards the inner wall of the hydrocyclone under centrifugal force and are eventually discharged from the bottom sand outlet, falling into fine screen below for secondary separation. The purified slurry flows out from the overflow outlet at the top of hydrocyclone and enters the next stage. The processing efficiency of the desander is closely related to the diameter of the hydrocyclone and the feed pressure. By properly matching these parameters, efficient separation of fine sand particles can be achieved.

Desilter:Core of fine purification

Desilter adopts hydrocyclone structure. The hydrocyclone diameter of the desilter is small (between 50-100mm), which is used to separate finer mud particles (particle size between 5-20μm) in the mud. It is key device for achieving fine purification of mud.

During drilling, mud particles can easily increase mud viscosity and reduce fluidity, affecting the drilling fluid's rock-carrying capacity and lubrication performance. Desilters, by enhancing centrifugal separation, separate and remove these fine particles, effectively controlling the solid content of the mud and maintaining its stability. Desilters are typically used in series with desanders to form "desand removal first, mud removal later" purification process, further improving the quality of mud purification.

Centrifuges: Gatekeepers of Ultimate Purification

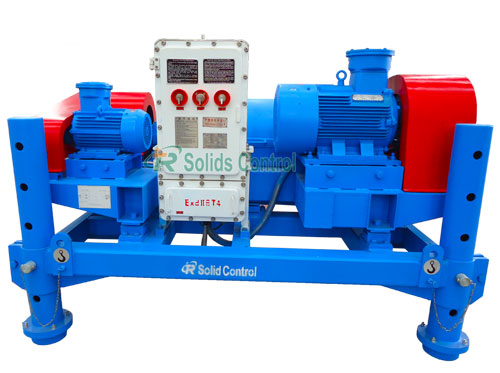

Centrifuges are the most precise separation equipment in solids control systems, used to separate ultrafine solid particles with diameter between 2-5 μm from drilling mud. They can even remove some colloidal particles, making them the core equipment for achieving "ultimate mud purification." They work by using high-speed rotating drum to generate powerful centrifugal force, rapidly separating solid particles from the liquid phase in the mud. The solid particles are deposited on the inner wall of the drum under centrifugal force and discharged through screw conveyor. The purified mud flows out from the other end of the drum and can be directly recycled for drilling operations.

The processing precision of centrifuge can be controlled by adjusting the drum speed and the differential speed between screw feeder and drum. It is suitable for drilling conditions with extremely high requirements for mud performance, such as horizontal wells and directional wells. In areas with strict environmental protection requirements, centrifuges can also effectively reduce the solids content of the mud, facilitating subsequent harmless treatment or recycling of the mud.

Auxiliary Solids Control Equipment

In addition to aforementioned separation equipment, the mud recycling system is also equipped with variety of auxiliary equipment to ensure stable system operation: First, vacuum degasser, used to remove dissolved natural gas, air and other gases from the mud to prevent mud "gas intrusion" from affecting drilling safety; Second, sand pumps and shear pumps, which provide power for the transportation of mud between various devices, while the shear pumps can fully shear the large molecular polymers in the mud to improve mud performance; Third, mud agitator and mud tank, used to store mud and prevent solid particles from settling, maintaining the uniformity of the mud.

II. TR Mud System Case: Integrated Application of Solids Control Equipment

TR Solids Control, well-known enterprise in China's mud recycling system company, is widely used in various fields such as oil and gas drilling, trenchless pipe jacking, and tunnel boring machine construction, thanks to its characteristics of "high-efficiency purification, energy saving and consumption reduction, and stable reliability." The following case study, using its application in shale gas field drilling project, illustrates the integrated effect of solids control equipment.

Case 1: Integrated Solids Control System for Oilfield Drilling

This shale gas field drilling project is located in Sichuan Province, with drilling depths exceeding 4,500 meters. The formation lithology is complex, with high sand content, and the drilling process requires the use of large quantities of high-performance drilling fluid. The project requires the mud recycling system to achieve solids removal rate of ≥95% and mud recycling rate of ≥90%, while also being able to withstand high-temperature and high-humidity field operating environments.

Configuration:High-frequency shale shaker + 10-inch Desander + 12-inch Desilter + Decanter centrifuge + auxiliary equipment + intelligent SCADA control system.

High-frequency shale shaker: It adopts double-layer screen with upper screen mesh of 120 mesh (separating particles larger than 125μm) and lower screen mesh of 200 mesh (separating particles larger than 75μm). The vibration frequency reaches 30Hz, effectively intercepting large rock cuttings generated during drilling, with solid phase removal rate of over 60%.

High-efficiency desander: Equipped with 6 hydrocyclones with diameter of 150mm, the feed pressure is controlled at 0.2-0.3MPa, which can separate fine sand particles of 20-75μm and has processing capacity of 120m³/h, further reducing sand content of mud.

Fine Desilter: Equipped with 12 small-diameter hydrocyclones with diameter of 50mm, it separates mud particles of 5-20μm, reducing the mud content of treated mud to below 3%.

Decanter centrifuge:Using variable frequency decanter centrifuge, the drum speed can reach 3000 r/min, which can separate ultrafine particles of 2-5μm, ultimately controlling the solid content of mud to within 1%, meeting the mud performance requirements of shale gas drilling.

Auxiliary equipment: Equipped with 2 vacuum degassers to remove natural gas components from mud, 4 sand pumps to ensure mud transportation power, and 8 100m³ mud tanks and agitators to achieve mud storage and homogenization.

The mud system achieved the following results after operation:

The efficiency of mud recycling has been significantly improved: the system has mud recycling rate of 92%. Originally, each well required about 80 tons of drilling fluid material, but after adopting this system, only about 10 tons need to be replenished. The cost of mud material per well has been reduced by more than 70%, saving the project owner more than 2 million yuan in total.

Solid phase removal effect meets the standard: After four-stage purification, the solid phase removal rate of the mud reaches 96%, the viscosity, density and other performance indicators of the drilling fluid are stable, effectively reducing the wear of drilling tools, increasing drilling efficiency by 15%, and shortening the drilling cycle of single well by 3-5 days.

Environmental pressure has been significantly reduced: waste mud emissions have been reduced by more than 90%. By solidifying the separated solid rock cuttings, "solid waste reduction and harmlessness" have been achieved, meeting local environmental protection requirements and avoiding the environmental pollution problems of traditional drilling.

Case 2: Subway Construction Slurry Treatment System

Configuration:shale shaker, desander, desilter, and shear pump combination system.

Effect:

The solids content of the mud was reduced from 30% to below 5%, preventing pipe blockage and improving construction efficiency.

The system reduces total amount of drilling waste and lowers the cost of subsequent solidification treatment.

Application scenarios: shield tunneling, trenchless engineering, and other fields with high requirements for mud performance.

The successful application of TR's mud system demonstrates that the purification effect of mud recycling system depends not only on the performance of single solids control device, but also on reasonable configuration and integrated optimization of the equipment.

The solids control equipment of mud recycling system is based on the core logic of "multi-stage separation". The shale shaker, desander, desilter and centrifuge respectively undertake the purification tasks of four levels: coarse, medium, fine and fine. With the help of equipment such as vacuum degasser and sand pump, complete mud purification and circulation system is formed. In shale gas field projects, TR's mud system not only reduces construction costs and improves efficiency but also achieves win-win situation for both environmental protection and economic benefits. As drilling projects increasingly demand higher levels of environmental protection and efficiency, the refinement and intelligent upgrading of solids control equipment will become the development trend of mud recycling systems, providing strong support for the green development of the drilling industry.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li