As core piece of equipment in drilling solids control systems, the selection of mud shale shaker directly affects the solids control effect, drilling efficiency, and cost control. Shaker Screen selection should consider factors such as "equipment compatibility, operating conditions matching, and solids control requirements."

TR Solid Control offers variety of mainstream screen types to meet different needs, based on material characteristics, screening accuracy, usage environment, and cost.

Mud properties and solid particle parameters

The primary basis for screen selection is based on size and concentration of solid particles and viscosity of drilling fluid. If solid phase in the drilling fluid is mainly fine particles (such as clay particles), high-mesh screen with closely spaced openings is required to improve interception accuracy. If it contains large number of coarse particles (such as rock cuttings), low-mesh screen with large openings should be preferred to avoid screen clogging and reduced processing efficiency. At the same time, high-viscosity drilling fluid increases the risk of particle adhesion, so shaker screen type with reasonable opening ratio and smooth surface is required to reduce mud retention.

Shale Shaker Equipment Parameters

Shaker Screen must be perfectly compatible with structure and performance of shale shaker. First, shaker screen size must strictly match the installation dimensions of screen box (such as length, width, and fixing holes) to ensure secure installation and prevent displacement or damage during vibration. Second, vibration parameters must be compatible; the shaker screen material strength must withstand the vibration frequency and amplitude of the equipment. For high-frequency vibrating equipment, more resilient shaker screen should be selected to prevent fatigue fracture. Third, the equipment's processing capacity must be considered; high-capacity shale shakers require screen meshes with high opening ratio to ensure efficient slurry flow and avoid processing bottlenecks.

Drilling Conditions and Operational Requirements

The requirements for screens vary significantly depending on the drilling scenario. In shallow well drilling, where cuttings are coarse and mud composition is simple, economical conventional shaker screens can be used. In deep and ultra-deep well drilling, where mud systems are complex (such as oil-based mud), solid particles are fine and highly corrosive, special screens with chemical corrosion resistance and high precision are required. In shale gas and horizontal well drilling, due to the large drilling fluid circulation volume and strict solid phase control requirements, high-strength, long-life screens should be selected to reduce replacement frequency and ensure continuous operation. In addition, in areas with high environmental protection requirements, screens with high interception efficiency should be prioritized to reduce waste mud treatment costs.

Shaker Screen Performance Indicators

The performance of shaker screen itself directly determines the effectiveness of its use and requires close attention:

● Mesh count and aperture ratio: Mesh count represents the size of shaker screen aperture (the larger mesh count, the smaller the aperture), while aperture ratio is ratio of screen aperture area to total shaker screen area. The two need to be balanced - to ensure sufficient mesh count under high precision requirements, while taking into account the aperture ratio to maintain the throughput.

● Material strength: It must be wear-resistant, tensile-resistant, and chemically corrosion-resistant to extend its service life;

● Structural stability: The weaving or forming process of shaker screen should ensure that screen holes are uniform and edges are firm, so as to avoid deformation or screen hole displacement during vibration.

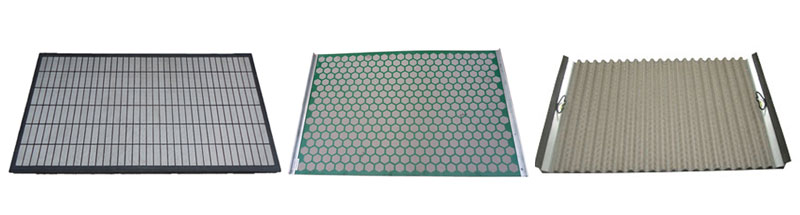

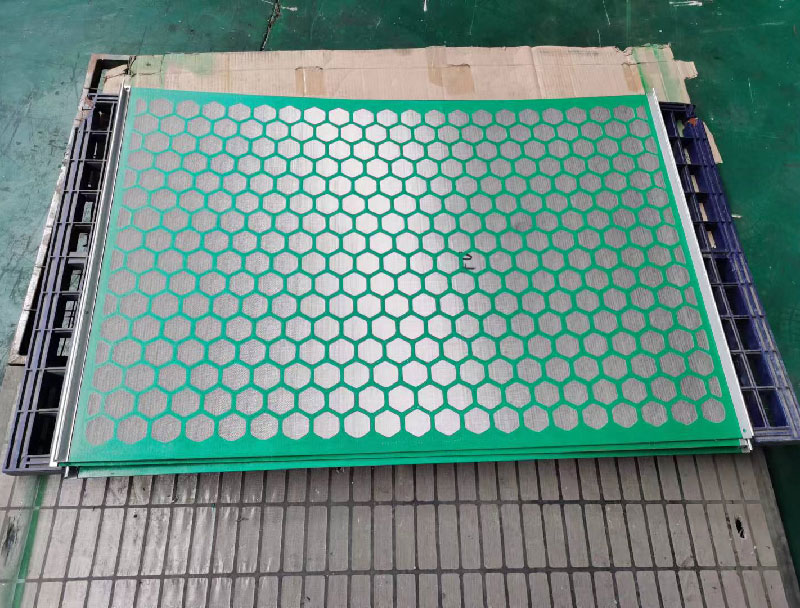

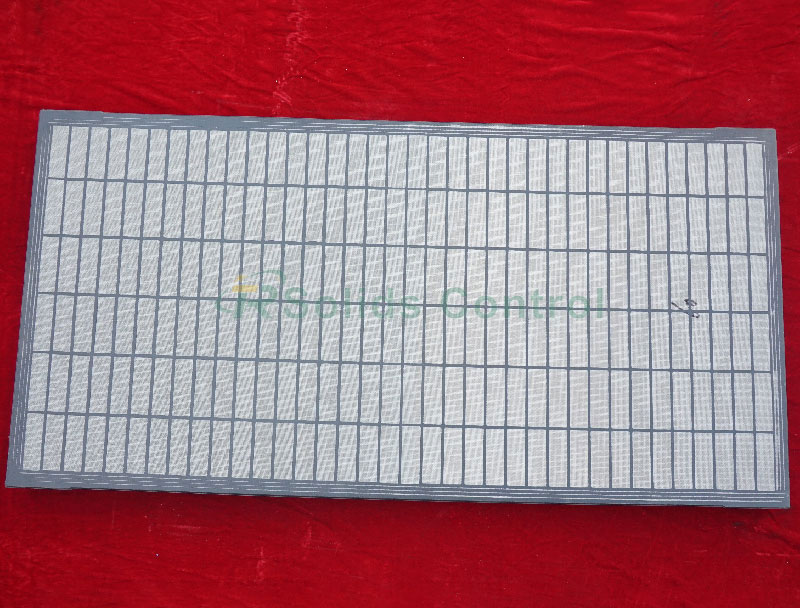

As a professional manufacturer of solids control equipment and accessories, TR Solids Control offers shaker screen products precisely designed for different drilling needs. Focusing on the core characteristics of "high-efficiency interception, durability and stability, and wide adaptability," the company provides following shaker screen types, covering the needs of multiple industries such as petroleum, mining, and food.

| Shaker Screen type | Material/Structural Features | Core Advantages | Applicable scenarios |

| Polyurethane screen | Made of polyurethane, with an open area ratio of 10%-50%. | High wear resistance (lifespan 3-5 times that of steel mesh), lightweight (only 1/3 the weight of metal mesh), and good impact resistance. | Oil drilling, high-wear mine screening |

| stainless steel screen | 304/316L stainless steel, resistant to acid and alkali corrosion. | Rust resistant, high screening accuracy, long service life | High-precision screening for chemical, food, and pharmaceutical industries |

| Composite structure screen | Metal wire mesh + polyurethane support composite structure | Balancing high strength and elasticity to extend service life | Complex working conditions (such as high hardness + high wear environment) |

| Frame screen | Wave screen / Flat screen, frame support | Stable structure, suitable for high-frequency shale shakers | Primary solids removal in oil drilling fluids |

| Hard groove edge screen | Wave screen / flat screen, hard frame | Highly impact-resistant, suitable for heavy-duty screening. | Coarse particle screening in mining and construction industries |

| Soft groove side screen | Flexible border design | Easy to install and adaptable to different screen box structures. | Temporary screening or rapid scene change |

| Derriok FLC Series | Wave screen / flat screen, API standard | Meets international industry standards, with high processing capacity and high efficiency. | Mainstream choice for solid phase control in oil drilling fluids |

| Swaco screen | High-performance polyurethane/stainless steel material | Wear-resistant and corrosion-resistant, compatible with various shale shaker models | General screening for petroleum and mining industries |

| Brandt VSM300 sieve | Special weaving process, high open hole ratio | High screening rate reduces the risk of clogging. | Screening of high-viscosity materials (such as drilling mud) |

Oil drilling industry: Opt for Derriok FLC series or Swaco screen from TR Solid Control, considering both wear resistance and processing efficiency.

Mining industry: High manganese steel screens or composite structure screens are recommended to cope with high hardness and high wear conditions.

Food/Pharmaceutical Industry: 316L stainless steel screens are used to meet hygiene standards and prevent material contamination.

High-viscosity materials: Choose Brandt VSM300 screens or polyurethane screens with high open area ratio to reduce risk of clogging.

Based on characteristics of TR solids control screens and actual drilling needs, the following logic can be used for rapid selection:

For conventional water-based mud and shallow well operations: 20-100 mesh woven wire mesh should be selected first to balance cost and efficiency;

Oil-based/synthetic-based drilling mud, medium-deep well operations: Use 50-150 mesh polyurethane screens to improve corrosion resistance and anti-clogging performance;

Shale gas horizontal well and ultra-deep well operations: 80-200 mesh composite screen is recommended to ensure high precision and long service life;

Large shale shakers and continuous operation scenarios: Pair with corresponding model frame screens to improve operation and maintenance efficiency.

TR Solids Control can provide customized screen solutions based on the user's shale shaker model, drilling conditions, and mud parameters, ensuring high degree of compatibility between the screen and equipment and operating conditions, maximizing solids control effect and screen lifespan. Shaker Screens specifications from API20 to API400 are available, which can replace international brand screens such as Derrick, Swaco, and Brandt, reducing procurement costs.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li