In oil drilling, pumps responsible for transporting oil sludge mainly include mud pumps, cuttings transfer pumps (sludge vacuum pumps), and mud screw pumps. They undertake the task of transporting oil sludge or drilling fluid in different scenarios. TR Solids Control is a manufacturer specializing in oil drilling solids control equipment. The following analysis will examine the functions and applications of solids transfer pumps that play different key roles in drilling fluid treatment systems.

Core Positioning:The "heart" of the drilling fluid circulation system, providing high-pressure power to pump mud into the wellbore and carry drill cuttings back.

Features::

TR model:TRSB8×6-14 (for drilling rigs above 3000 meters), TRSB8×6-11 (for drilling rigs below 3000 meters), etc., with power ranging from 7.5-75kW, flow rate from 20-355m³/h, and head from 21-61m.

Structural advantages:

The pump body is made of high wear-resistant alloy cast iron, ensuring a long service life.

SKF bearings + mechanical seal + packing seal provide double protection, making it 5 times more wear-resistant than ordinary pumps.

The impeller features a wide flow channel design and is made of high-chromium alloy, making it wear-resistant.

functional diversity:

Main circulation pump: Provides high-pressure drilling fluid (up to 35MPa or higher) to the wellbore.

Auxiliary functions: desanding/desilting device slurry supply, jet mixing, mud pump replenishment/grouting.

Application scenarios:

Conventional oil and gas drilling main circulation system

Horizontal directional drilling (HDD) and Shield tunneling mud circulation

Solid control equipment (Desander、Desilter)Pulp supply system

core positioning:Negative pressure suction + conveying of drill cuttings/sludge solves the problem of transferring solid-liquid mixtures.

Features:

TR model:TRSP-40L(40m³/h)、TRSP-25W(25m³/h)、TRSP-20L(20m³/h)、TRSP-10L(10m³/h)

Technical Highlights:

Fully pneumatic design: requires no electricity, has excellent explosion-proof performance, and is suitable for dangerous areas such as offshore platforms.

Super strong suction: vacuum level reaches 550-800KPa, maximum suction distance 50m, exhaust distance 1000m.

High throughput capacity: Can transport media with solid particles ≤70mm in diameter and a solid content of up to 80%.

Structural features:

The seal-free design avoids the leakage problems of traditional pumps.

It has strong self-cleaning ability, is not prone to clogging, and is easy to maintain.

Application scenarios:

Drilling cuttings/waste mud collection and transportation

The material discharged from the vibrating screen is transferred to the drying screen/centrifuge Dryer.

Tank cleaning and drainage of underground water

Environmental solid waste treatment and river dredging

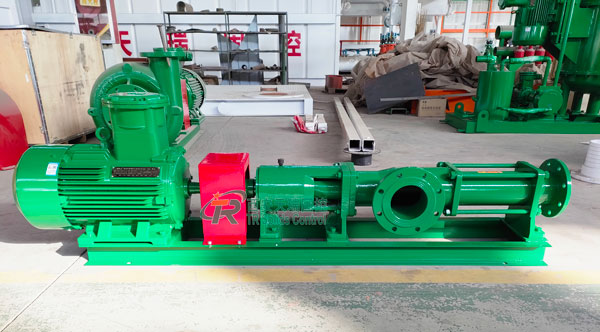

core positioning:High-viscosity, high-solids-content media "stabilized conveyors" are particularly suitable for centrifuge slurry supply and sludge treatment.

Features:

TR Model:TRG10A-040 to TRG90A-220, flow rate 10-90 m³/h, pressure 0.3 MPa, power 4-22 kW

Working principle:

A single screw (rotor) rotates eccentrically within a rubber stator, forming a sealed chamber to propel the medium.

The medium flows axially and uniformly within the pump without agitation or shearing, thus maintaining its original physical properties.

Performance advantages:

Extremely high adaptability: Can transport media with extremely high viscosity, containing solid particles, and fibers.

Stable flow rate without pulsation, stable pressure, suitable for precision metering.

With a compact structure and few vulnerable parts (only the rotor and stator), maintenance is convenient.

Material selection:

Standard type: Rotor is made of stainless steel, stator is made of synthetic rubber.

Special type: Made entirely of stainless steel, suitable for highly corrosive environments.

Application scenarios:

The mud purification system uses a centrifuge for mud supply (without shearing the mud, ensuring effective separation).

Drilling waste disposal and wet mud transport

Oilfield oily sludge treatment

Conveying high-viscosity materials such as chemicals and pharmaceuticals

| Parameter index | Mud pumps (TRSB series) | Drill cuttings transfer pump (TRSP series) | Screw pump for mud (TRG series) |

| Drive mode | Motor drive | Compressed air driven (pneumatic) | Motor driven (variable frequency optional) |

| Flow rate | 355m³/h | 10-40m³/h | 10-90m³/h |

| Output pressure | 61m Lift | Negative pressure (550-800 kPa vacuum) | 0.3MPa |

| Applicable material | Medium and low viscosity drilling fluid | High solids content (≤80%) drill cuttings / sludge | High viscosity, particulate media |

| Particles pass through | ≤30mm | ≤70mm (Large model) | ≤20mm (depends on gap) |

| Energy consumption characteristics | High power 75kW | Energy consumption is related to gas volume | Relatively energy efficient(≤22kW) |

| Explosion-proof performance | Optional explosion-proof motor | Intrinsically safe (no electricity required) | Optional explosion-proof motor |

| Maintenance difficulty | Medium (impeller and other parts are easily damaged) | Low (no sealing structure) | Low (rotor/stator damage only) |

| price range | higher | medium | medium |

Choosing a mud pump (TRSB):

High-pressure, high-flow-rate drilling fluid circulation is required (e.g., for deep/ultra-deep wells).

Provide a stable slurry supply for the desander/desilter.

Power source for jet mixing device

Mud pump-assisted injection/replenishment

Choosing a drill cuttings transfer pump (TRSP):

Drill cuttings/sludge collection and long-distance transportation (≤1000m)

Operating in explosion-proof areas such as offshore platforms

Waste treatment with high solids content (≥50%)

Vacuum suction function is required (e.g., for tank cleaning operations).

Choosing a mud screw pump (TRG):

Centrifuge-fed slurry (no shearing required)

High-viscosity mud/sludge transportation

Handling of fibrous or fragile media

Precision delivery requiring stable, pulse-free flow

TR Solids Control's three major pump types form a "golden triangle" in drilling fluid treatment: mud pumps handle high-pressure circulation, cuttings transfer pumps focus on transferring cuttings after solid-liquid separation, and mud screw pumps handle precise delivery of high-viscosity media. Selecting the appropriate pump type based on actual operating conditions (media characteristics, pressure/flow requirements, environmental conditions) can significantly improve drilling efficiency and reduce maintenance costs.

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li