Mechanical seals are dynamic sealing devices used to prevent the fluid in a water pump's volute from flowing out through the pump shaft. They are sophisticated and complex mechanical components, making them key components in various pump systems.

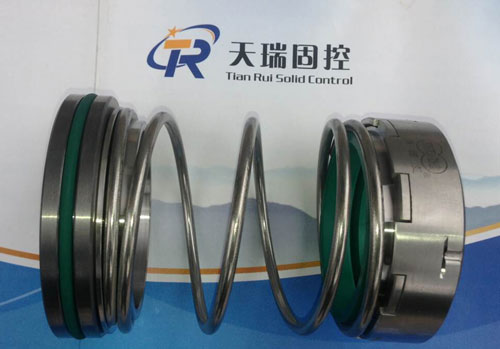

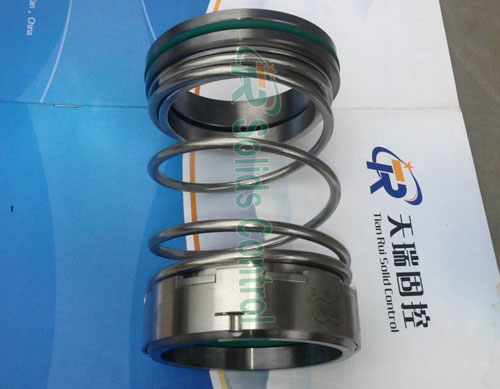

Mechanical seals rely on the two end faces of the static ring and the dynamic ring to be pressed tightly, and under the action of fluid pressure and the spring force of the compensation mechanism, axial cross-section sealing is achieved to prevent fluid leakage.

Mechanical seals can be categorized as single-face, double-face, or multi-face, depending on the number of friction pairs between the dynamic and static seals. Double-face seals offer better leakage control, but require higher installation precision. Many modern double-face seals are assembled into a cartridge seal. This type of seal integrates the entire set of components, including the dynamic and static seals, compensating mechanism, auxiliary seal ring, sleeve, and gland, into a single unit. This eliminates the need for on-site commissioning and allows for complete assembly and disassembly, making installation easy and reducing human error. However, cartridge seals are more complex, bulky, and expensive.

There are two common water leakage situations:

Water leaks at the contact point between the inner ring of the rotating ring and the shaft

Cause: Impurities or particulate matter in the medium

Solution: Check the front water inlet for a filter and damage.

Damage to the outer ring of the stationary ring

Cause: Dry grinding without water or dry grinding caused by cavitation

Solution: Exhaust air before use and check the piping for potential cavitation risks.

• Versatile stuffing box

• One-piece casing

• Casing gasket receded for protection

• Back vanes reduce collection of solids at stuffing box

• Long-life, no-adjustment mechanical seal available for near zero leakage

• Replaceable shaft sleeve

• Lip seals for maximum bearing protection

• Duplex angular contact bearings

• Thicker, stronger concentric casings

• Full pipe diameter entrance for minimum turbulence and maximum efficiency

• Single row roller bearings for increased bearing life

• Easily accessible front access drain

• Reduced high bearing loads

Address: No.2 Hu·ochang Rood, Yangling District, Xianyang City, Shaanxi Province, China

Tel: +86-13186019379

Wechat: 18509252400

Email: info@mudsolidscontrol.com

Contact: Mr.Li